Why campro engines fail on crank!!! Campro 1.6 vs 4g92p

- Thread starter speed2horizon

- Start date

- Replies 188

- Views 112K

-

See what others are reading now! Try Forums > Current Activity

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

spoon civic

Known Member

Hi everyone. 2 weeks ago, I was hanging around my mechanic's place doing nothing better than sleeping, gossiping and talking CXCK and laughing laudly... Realizing my mechanic was busy dismentalling a CAMPRO 1.6 engine to overhaul, I decided to get my hands dirty and help him up...

As we were busy dismentalling the engine, we chat about CAMPRO 1.6 BOT failure on Crank and we realizeD BOT DOES NOT FAIL THE CAMPRO CRANK, BOT ONLY ACCELERATE THE FAILING PROCESS OF THE CRANK.

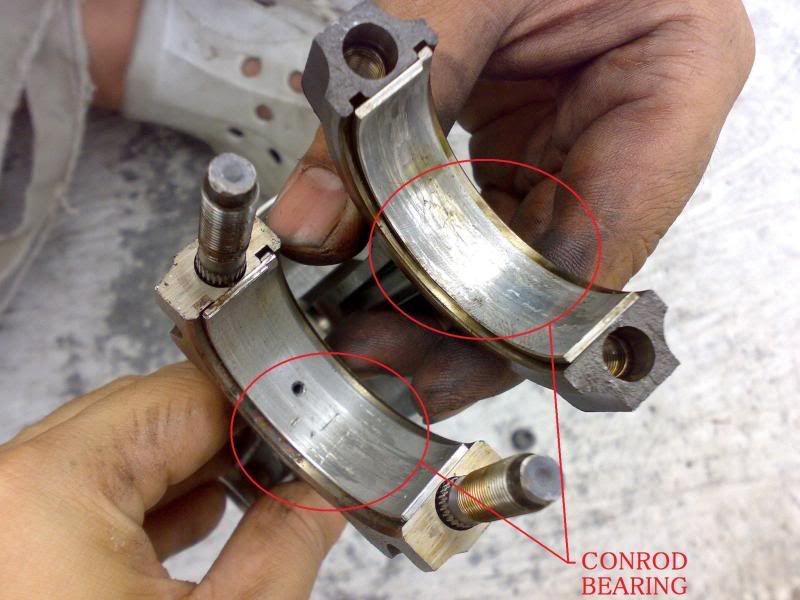

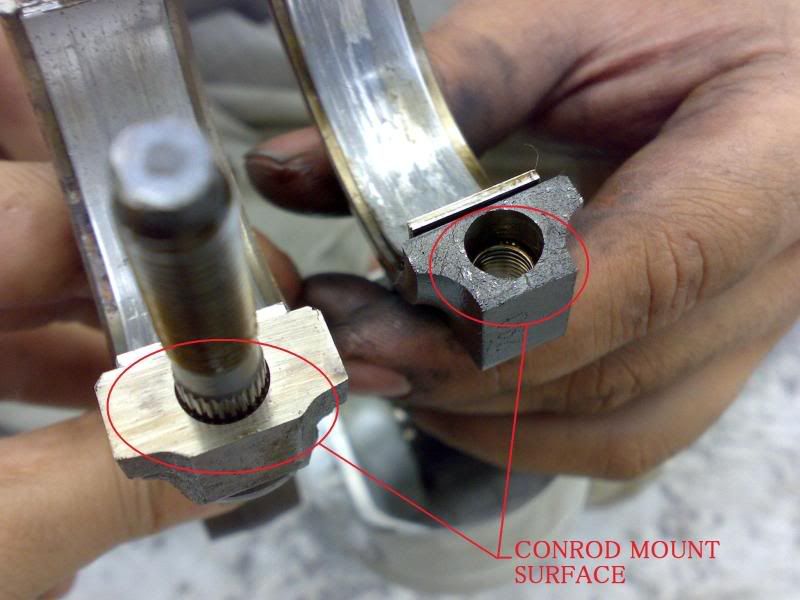

And we also realize that the cause of the Crank failure is actually from the CONROD. Here are some picture I've taken in comparison between a CAMPRO 1.6 CONROD vs a 4G92P CONROD.

IMAGE 1

.

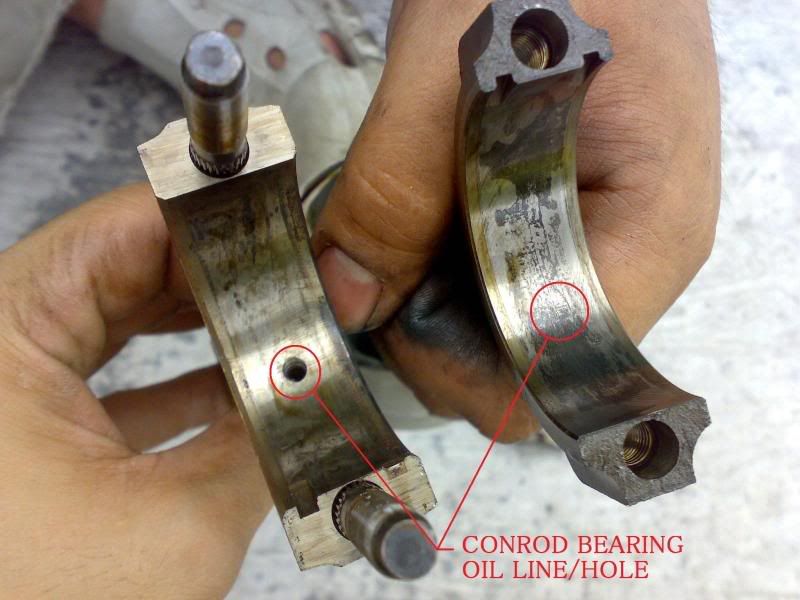

The holes are for the engine oil to enter the conrod bearing for lubrication and cooling furpose as the Crank is turning within the Conrod bearing. without sufficient lubrication, the crank will wear out the conrod brearing.

IMAGE 2

An Image showing the Conrods without the bearing.

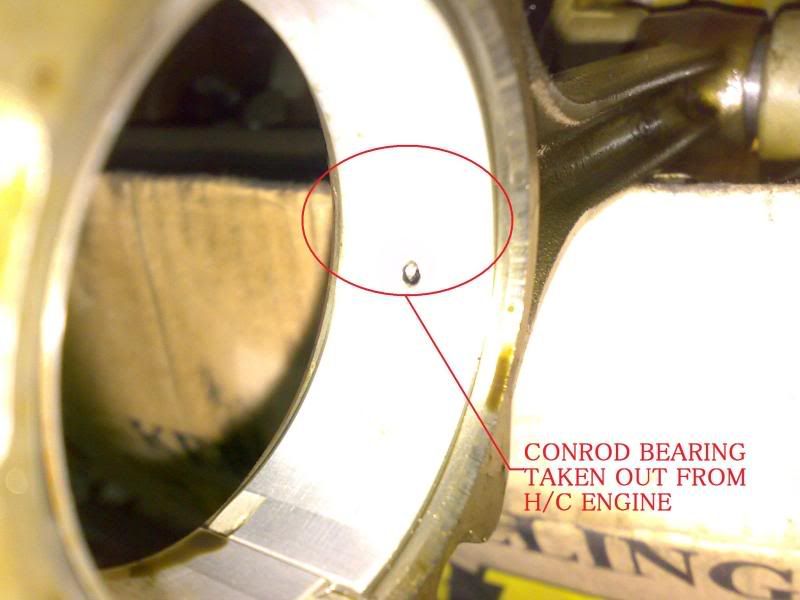

IMAGE 3

This is the CONROD Bearing used for around 100,000KM running all time on Semi Synthetic Oil. Owner claim he seldom gasak the engine. Realize that the bearing is ot smooth anymore. And sooner or later, it'll create higher friction to the cranks.

IMAGE 4

This is a CONROD BEARING from a 4G93 mitsu engine kosong from halfcut. Not sure about the date.

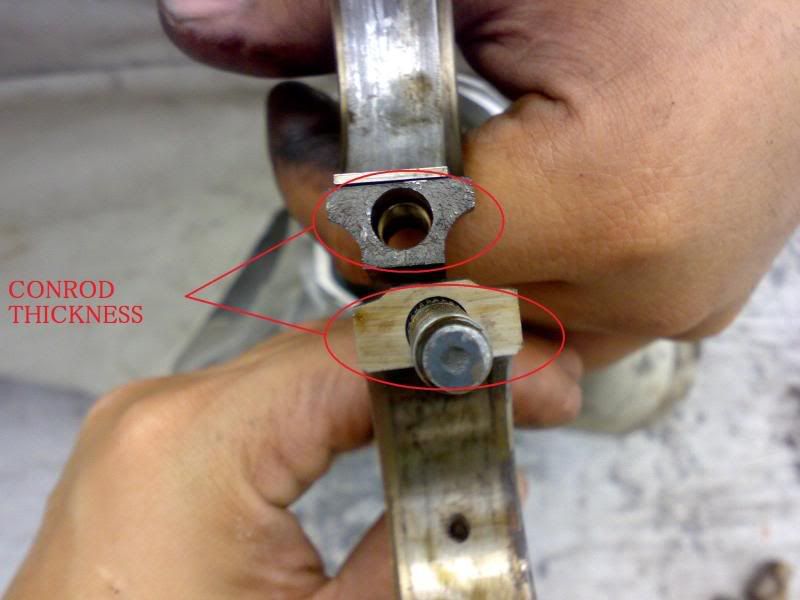

IMAGE 5

Take a look at the CONROD thickness comparison. Should voice anything else..? U judge.

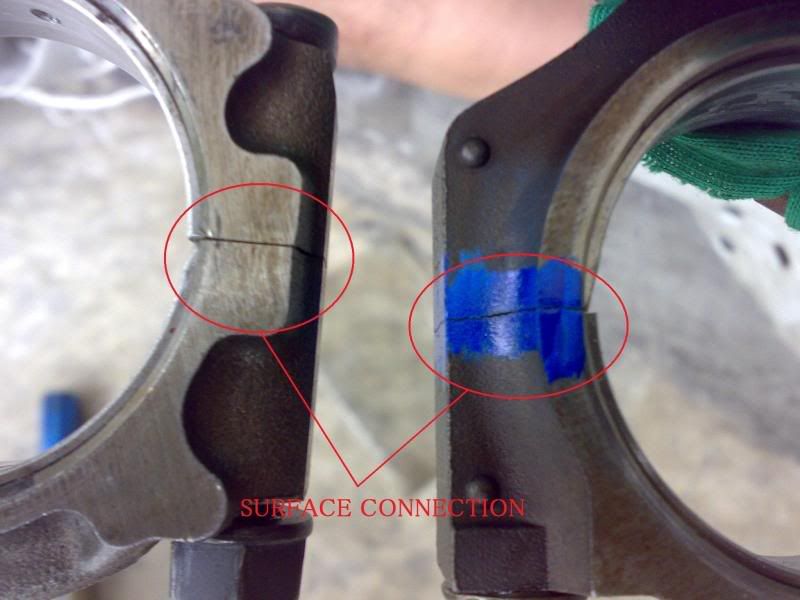

IMAGE 6

Now, lets compare the surface where the lower conrod and upper conrod have their contact. What do you think..? Would the CAMPRO CONROD seat properly flat..?

IMAGE 7

Here is the pisture showing the lower part of the CONROD attached with the upper part of the CONROD between 4G92P and CAMPRO 1.6. Obviously, after attached, The CAMPRO 1.6 are not flat at all.

IMAGE 8

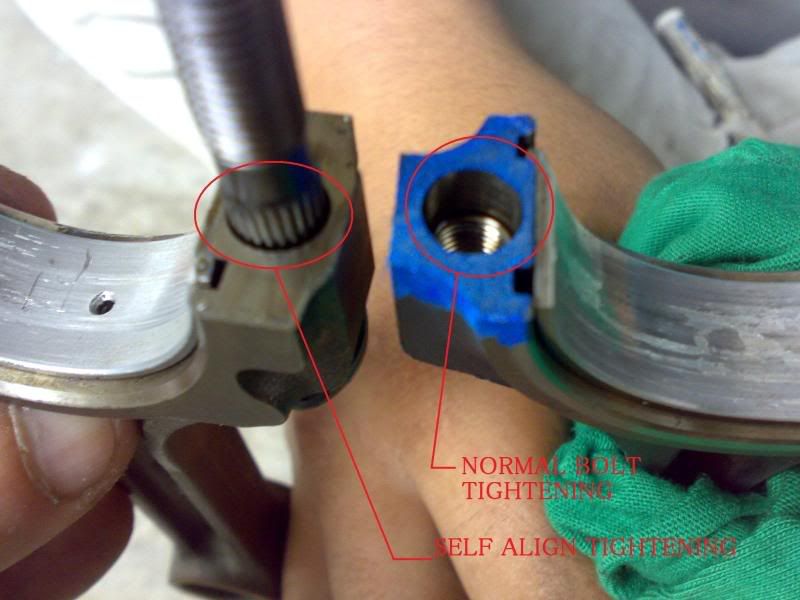

Please note the difference between the CONROD tightening method difference between the 4G92P and the CAMPRO 1.6. If u try fitting in the lower part of the MITSU's CONROD into the MAIN CONROD, U'll realize it's harder to go in at the vertical lines of the Stuts. The diameter of the portion with vertical lines are bigger so that the BOTTOM CONROD witll self align to the center of both Stuts. So, they will be flat when tightened.

Where else CAMPRO's does not use any method to aligned the tightening holes. They uses normal screw tightening method (Refer IMAGE 10). And the result, U can refer to IMAGE 9

IMAGE 9

IMAGE 10

IMAGE 11

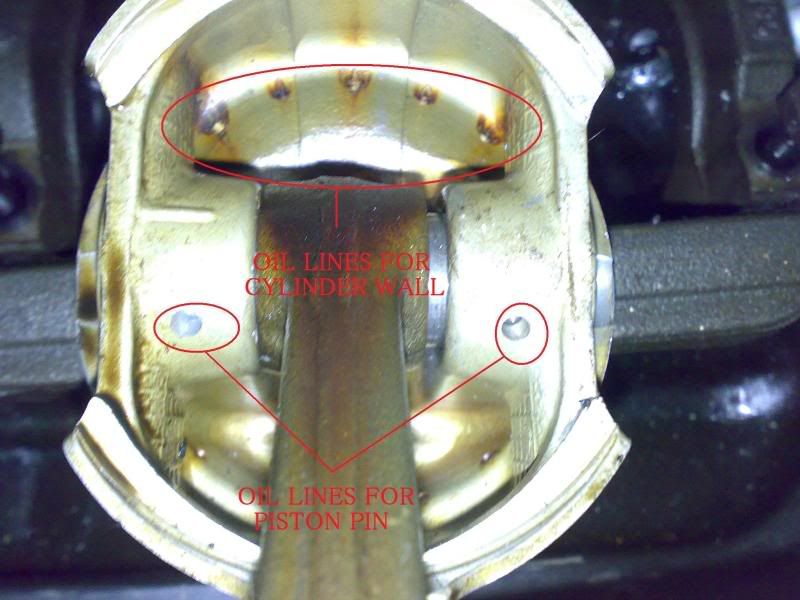

Above image shows 4G92P PISTON DESIGN

IMAGE 12

Above image shows CAMPRO 1.6 PISTON DESIGN

Obviously, the MITSU's PISTON have more holes for the engine oil to slip through to the cylinder wall for lubrication purpose compare to the CAMPRO PISTON.

Also, the Piston PIN of CAMPRO PISTON also does not have holes for the oil to slip through for the pin lubrication.

Well, not having any intention to insult, Just sharing what I know. If this is these things are designed in such a way on purpose not because of cost cutting, please clarify and prove me wrong. I am always open minded to accept. Cheers....

Thanks for reading.

i vote for your info bro....but whaT can we get if we save 10 cents but we lost rm10....rite?

- Joined

- Jun 4, 2006

- Messages

- 2,798

- Points

- 1,683

i vote for your info bro....but whaT can we get if we save 10 cents but we lost rm10....rite?

Well in automotive manufacturing. Time and cents are crucial for every parts produced. But all paper calculation will only prove 85% of the accuracy. The remaining will be left on the road test...

IF, there's nothing wrong with the design. I don't see any reason for proton increasing the oil holes in their newer campros... Changing connecting rods material and crank design.

Like said, it may not be purely cost down purpose. But the conrod screw looks like a normal high tensile screw u can buy from the Bolts and nuts shop... Not sure abt the material. But there are definitely better way to fasten the cap to the rod.

My neo cps engine currently developing a wrist pin noise or so they say. it is not like a con rod bearing noise which sounded like a deep thud low frequency noise. it is more like hyd lash noise hi freq but metallic-like..my guess is the lash is sticky beyond help..power is not lost..only heart breaking noise..haiyaa pening already..during 6 years of driving this car, i have overhauled this engine for 4 times..if this turns out to really be the wrist pin noise, i am out of words..

ok guys..it dieded hmm

ok guys..it dieded hmm

that escalated rather quickly!!

time for proper rebuild

that escalated rather quickly!!

what seems to bother me was that the engine did not lose any power although the bearings were about to fail..hahaha whacked it till it blew a hole tru the block

Well i transplanted a mivec already..quite scared of going down campro road again after 4 times of engine breakage

Sent from my CPH1607 using Tapatalk

Sent from my CPH1607 using Tapatalk

Similar threads

- Replies

- 19

- Views

- 11K

- Replies

- 2

- Views

- 3K

- Replies

- 2

- Views

- 5K

- Replies

- 13

- Views

- 8K

- Replies

- 8

- Views

- 9K

- Replies

- 7

- Views

- 3K

- Replies

- 3

- Views

- 5K

- Replies

- 96

- Views

- 32K

New Posts

- Replies

- 0

- Views

- 230

- Replies

- 0

- Views

- 228

- Replies

- 0

- Views

- 198

- Replies

- 0

- Views

- 289

The Marketplace Latest

Posts refresh every 5 minutes

Happy New Year! The Dragon Year beckons a fresh start with (hopefully) more prosperity and happiness to every automotive enthusiast. After a few days of celebration and joyous gatherings, a few...Evo 9 Headlamp and Tail Lamp set for sale

Tail Lamp: RM 1900.00

Head Lamp: RM 2200.00

Very good condition

Remus 017 3666 666

Tail Lamp: RM 1900.00

Head Lamp: RM 2200.00

Very good condition

Remus 017 3666 666

anyone tried hks pfc fcon here b4? i have some question to ask.. can i change the map sensor(fcon) to diff. brand of map sensor such as microtech 25psi map sensor?

Recent Posts

-

Upping Wira 1.5 MMC performance

- Started by Nyfka

- Car Modification

-

AMPANG mari!!ZTH member

- Started by shahaff_07

- Groups and Meets

Search

Enjoying Zerotohundred?

Log-in for an ad-less experience