Also got my header ceramic coated and installed. A lot of piping work when replacing the former header to this one which involves a lot of modification of pipe and numerous trial & error of fitting problem when doing this on my own at home without any welding facilities. Have to do piece by piece and visit the welding shop numerous time as the car is stranded at home on stands. A lot time and effort put in. Car is in running condition now after been sleeping for a long time.

My MR2 turbo upgrade project

- Thread starter Green06

- Start date

- Replies 98

- Views 22K

-

See what others are reading now! Try Forums > Current Activity

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My next coming project of upgrading..........Standalone DIY MegaSquirt ECU....to replace the OEM ECU and to do away with AFM unit, this might take sometime to install and others coming soon.......See photos, ECU & wiring harness ready and will be doing wasted spark ( distributor less)........my plan/goal.

Attachments

This is not so much about the car..but the labor of love. MR2. ahh.. would look great in dark blue

Not bad of a job however could be more professional if they were to work the details such as remove the machining burrs and wash the parts after completion. Otherwise would be great piece of work when someone would take all the trouble to make such a cheap alternative than buying the OEM imports.

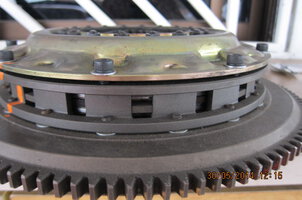

Here are the photos...........yet to get it installed and test out. Will need some run in to perform well.

Here are the photos...........yet to get it installed and test out. Will need some run in to perform well.

Attachments

- Joined

- Feb 2, 2006

- Messages

- 6,615

- Points

- 1,713

Also got my header ceramic coated and installed. A lot of piping work when replacing the former header to this one which involves a lot of modification of pipe and numerous trial & error of fitting problem when doing this on my own at home without any welding facilities. Have to do piece by piece and visit the welding shop numerous time as the car is stranded at home on stands. A lot time and effort put in. Car is in running condition now after been sleeping for a long time.

what thickness of those header did you use?

My next coming project of upgrading..........Standalone DIY MegaSquirt ECU....to replace the OEM ECU and to do away with AFM unit, this might take sometime to install and others coming soon.......See photos, ECU & wiring harness ready and will be doing wasted spark ( distributor less)........my plan/goal.

Any reason why mega squirt? not the other brand of stand alone?

I.. yah......this is the 3rd. time I am trying to post some work done on my project and always could not get it done correctly, this showed that I am away for too long .............hope this time will work.

All this while I was having problem as my Mac Air book was acting funny and have to reformat. Lost my USB to Serial RDS232 comm link. Tried numerous time to finally downloaded the correct software that works with my Mac.

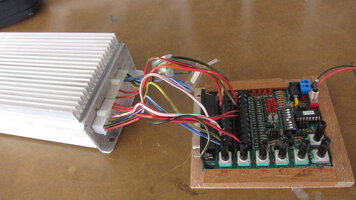

Upgraded to MS2 with daughter board and loaded with ver.3.3.2 firmware. See attached photos.

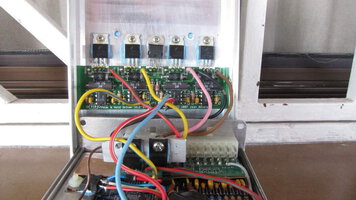

Added an external heatsink ( overkill ) which will help to keep my injector driver cool. See photos.

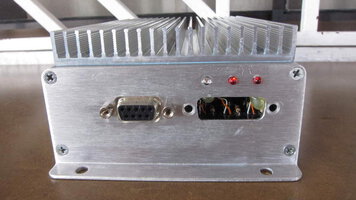

Replaced the serial connector to higher amperage connector. See photo.

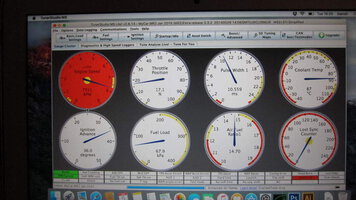

Was having issue with RPM synch with my crank sensor and finally bought and paid the paid version Tuner Studio and problem gone, I got RPM synch with my crank sensor ( actual live tested ).See photo.

This show "no free lunch" is better. Anyway those dudes spend their sweat & time needs to get their lunch paid which is fair !!

Tested RPM cut at 7700 rpm, spark cut works perfectly. Its good to test with the stimulator and ensure all function works before installing than to ruin the engine. See photo.

Tried to attach photos...........hope it works............

All this while I was having problem as my Mac Air book was acting funny and have to reformat. Lost my USB to Serial RDS232 comm link. Tried numerous time to finally downloaded the correct software that works with my Mac.

Upgraded to MS2 with daughter board and loaded with ver.3.3.2 firmware. See attached photos.

Added an external heatsink ( overkill ) which will help to keep my injector driver cool. See photos.

Replaced the serial connector to higher amperage connector. See photo.

Was having issue with RPM synch with my crank sensor and finally bought and paid the paid version Tuner Studio and problem gone, I got RPM synch with my crank sensor ( actual live tested ).See photo.

This show "no free lunch" is better. Anyway those dudes spend their sweat & time needs to get their lunch paid which is fair !!

Tested RPM cut at 7700 rpm, spark cut works perfectly. Its good to test with the stimulator and ensure all function works before installing than to ruin the engine. See photo.

Tried to attach photos...........hope it works............

Last edited:

Attached are the photos............:sleep:

Attachments

-

RPM cut tested-works fine.jpg76.3 KB · Views: 197

RPM cut tested-works fine.jpg76.3 KB · Views: 197 -

Removed the DB connector and upgrade to better connector.jpg64 KB · Views: 193

Removed the DB connector and upgrade to better connector.jpg64 KB · Views: 193 -

Modified with external heat sink for the Injetor driver.jpg59.5 KB · Views: 188

Modified with external heat sink for the Injetor driver.jpg59.5 KB · Views: 188 -

Injector driver board attached to top cover.jpg80.5 KB · Views: 198

Injector driver board attached to top cover.jpg80.5 KB · Views: 198 -

Connect up with stimulator.jpg70.7 KB · Views: 189

Connect up with stimulator.jpg70.7 KB · Views: 189

More photos........

Attachments

-

Upgraded connector handling higher amperage.jpg69.1 KB · Views: 217

Upgraded connector handling higher amperage.jpg69.1 KB · Views: 217 -

Upgraded to MS 2 daughter board version 3.3.2 firmware.jpg115.9 KB · Views: 229

Upgraded to MS 2 daughter board version 3.3.2 firmware.jpg115.9 KB · Views: 229 -

RPM cut tested-works fine.jpg76.3 KB · Views: 212

RPM cut tested-works fine.jpg76.3 KB · Views: 212 -

RPM synch tested works fine with crank sensor.jpg80.5 KB · Views: 223

RPM synch tested works fine with crank sensor.jpg80.5 KB · Views: 223 -

Removed the DB connector and upgrade to better connector.jpg64 KB · Views: 222

Removed the DB connector and upgrade to better connector.jpg64 KB · Views: 222

Next will have to figure out how to run the wire loom, relays, fuses etc. Coil pack installation is another headache, where to put it? Any suggestion? Will be using back the spark plug cable ( TRD ).

Planning to modify the intake manifold to side feed as the mid feed is having uneven distribution of air since #2&3 cylinder will always run leaner. Hope with a side feed will solve this issue. Also to modify an intercooler to top mount for the shortest pipe run. Wow........looks like tons of work........for DIYer.

Planning to modify the intake manifold to side feed as the mid feed is having uneven distribution of air since #2&3 cylinder will always run leaner. Hope with a side feed will solve this issue. Also to modify an intercooler to top mount for the shortest pipe run. Wow........looks like tons of work........for DIYer.

Waoh its been a year.

Next will have to figure out how to run the wire loom, relays, fuses etc. Coil pack installation is another headache, where to put it? Any suggestion? Will be using back the spark plug cable ( TRD ).

Planning to modify the intake manifold to side feed as the mid feed is having uneven distribution of air since #2&3 cylinder will always run leaner. Hope with a side feed will solve this issue. Also to modify an intercooler to top mount for the shortest pipe run. Wow........looks like tons of work........for DIYer.

maybe go for air-water type intercooler? atleast increase in item to install makes it easier for DIY-er

Similar threads

- Replies

- 19

- Views

- 9K

- Replies

- 32

- Views

- 8K

- Replies

- 24

- Views

- 9K

- Replies

- 52

- Views

- 11K

- Replies

- 3

- Views

- 3K

- Replies

- 4

- Views

- 2K

- Replies

- 5

- Views

- 2K

- Replies

- 34

- Views

- 8K

- Replies

- 9

- Views

- 3K

The Marketplace Latest

-

Chrome delete

- Started by jeff6126

- Exterior and Body

Posts refresh every 5 minutes

hello guys.. need your kind help.. i juz change my perodua myvi rim to 15' sport rim (advanti) et35 7jj with 195/55/15 tyre size.. but my rear tyre hit the fender when full loaded or even when one person seat at the...

First of all I gotta thank all the sifu here about last time teaching me how to send my car from japan to malaysia. Finally I found my way to send it back.

I am noob in GTR, hope can get more advises from you all...

I am noob in GTR, hope can get more advises from you all...

anyone know how to install this turbo timer?

got wiring diagram as well? i send to aksesori shop..they juz conect d turbo timer function...others function cannot works la...help

got wiring diagram as well? i send to aksesori shop..they juz conect d turbo timer function...others function cannot works la...help

Recent Posts

-

Tire Price list Zth

- Started by xbalance2002

- Wheel And Tyre

Search

Enjoying Zerotohundred?

Log-in for an ad-less experience