- Joined

- Oct 10, 2005

- Messages

- 588

- Points

- 5,018

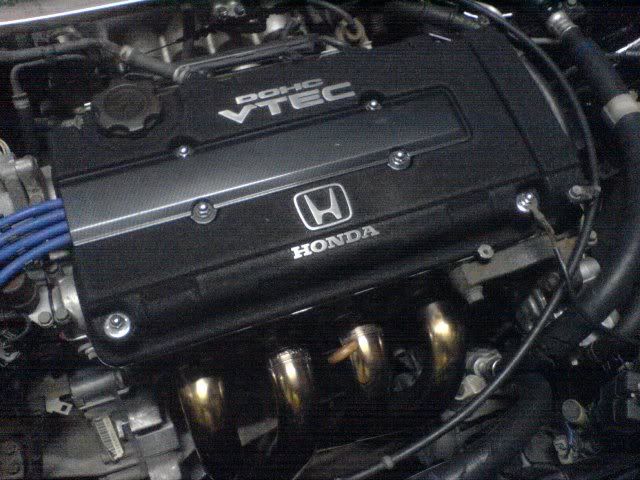

Before Pics :

http://img404.imageshack.us/img404/8086/cimg4193sk3.jpg

During DIY :

http://img264.imageshack.us/img264/4823/cimg4203zn7.jpg

After completed :

http://img227.imageshack.us/img227/2567/cimg4241lu0.jpg

After Pasang :

http://img513.imageshack.us/img513/978/cimg4243ec3.jpg

After 2 Rempit 1st-2nd Gear :

http://img474.imageshack.us/img474/7804/cimg4244xc4.jpg

Extractor : rm1200

Drill and Wire Brush + sand paper + Miscellaneous : rm170

Satisfaction : Priceless :regular_smile:

Also included is my apex'i N1 purple about to go on :

http://img260.imageshack.us/img260/7812/cimg4225pm8.jpg

And Fake HKS 304 replica selling for rm80.....2.5".....come with quarter piping for ek 4 door (Hint : Good way to annoy neighbours!) :

http://img398.imageshack.us/img398/2521/cimg4246hk3.jpg

A special Thanks to Mr Shiroitenshi for the great DIY guide, Ah heng exoz in usj 1 for lending me their machine to polish for free and to my GF who help me sandpaper the header AHAHAH!!

http://img404.imageshack.us/img404/8086/cimg4193sk3.jpg

During DIY :

http://img264.imageshack.us/img264/4823/cimg4203zn7.jpg

After completed :

http://img227.imageshack.us/img227/2567/cimg4241lu0.jpg

After Pasang :

http://img513.imageshack.us/img513/978/cimg4243ec3.jpg

After 2 Rempit 1st-2nd Gear :

http://img474.imageshack.us/img474/7804/cimg4244xc4.jpg

Extractor : rm1200

Drill and Wire Brush + sand paper + Miscellaneous : rm170

Satisfaction : Priceless :regular_smile:

Also included is my apex'i N1 purple about to go on :

http://img260.imageshack.us/img260/7812/cimg4225pm8.jpg

And Fake HKS 304 replica selling for rm80.....2.5".....come with quarter piping for ek 4 door (Hint : Good way to annoy neighbours!) :

http://img398.imageshack.us/img398/2521/cimg4246hk3.jpg

A special Thanks to Mr Shiroitenshi for the great DIY guide, Ah heng exoz in usj 1 for lending me their machine to polish for free and to my GF who help me sandpaper the header AHAHAH!!

Last edited: