- Joined

- Feb 6, 2007

- Messages

- 589

- Points

- 1,516

http://www.zerotohundred.com/uploads/meraboy/Chery-1.jpg

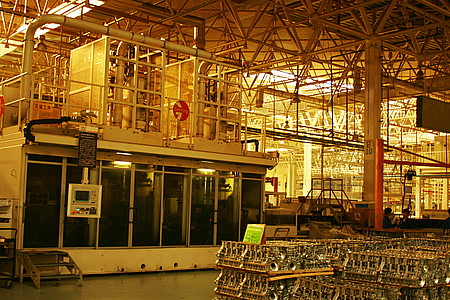

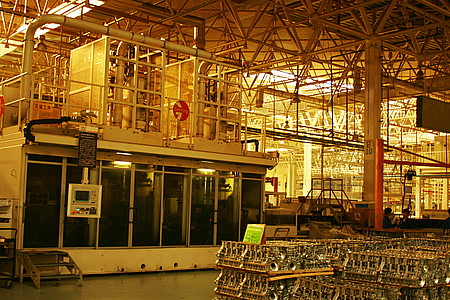

The Wall Street Journal was allowed behind the scenes at Chinese automaker Chery 奇瑞, a rare privilege in China. The reporter didn't discover any top-secret plans for world domination or even a rendering of what Dodge's Chery-made car would look like. But he did see German and Italian robotics being used on production lines staffed by $1-an-hour workers 16 hours a day. It's a combination the story says should be good for global success.

In Chery's research center, engineers are developing 40-50 new models and the company is building a new production line capable of turning out 700,000 cars a year.

Chery chairman Yin Tongyao says they hope their relationship with Chrysler will allow Chery to hone its cars and streamline its production process. "People look down on our products. There are many doubts about our safety and quality," says Yin says in the WSJ piece. "If we work together with Chrysler, we can go global faster."

This year, it expects to sell more than 400,000 compacts, SUVs and sedans, such as these being prepped for assembly earlier this month at the company's sprawling production complex in Wuhu 芜湖, in east-central China.

This summer, Chery signed a deal to make cars for sale under Chrysler's Dodge brand -- the first time one of Detroit's Big Three has outsourced the production of entire vehicles to a Chinese company. At left, workers on the assembly line in Wuhu.

Tom LaSorda, president and vice chairman of Chrysler, says a visit to Chery's factories in 2006 convinced him the company's production was up to snuff. "Everything was very familiar," he says.

The Wuhu plant, like nearly all mass-production factories, relies on the assembly line, first developed in Detroit in the early 1900s by Ford Motor Co. founder Henry Ford.

Chery has hastened its growth by relying on Western technology, such as the Italian-made robots, left, that it uses to assemble its engines in Wuhu.

The engine plant also has German-made precision-milling machines.

The plant's paint shop is a turn-key project, ordered in one piece from a manufacturer in Germany.

The paint process involves dipping the entire car nose-first in a giant vat.

After the paint has dried, the finish gets a close inspection.

Near the end of the assembly line, the cars get a fill-up.

Last stop: A quality check, looking at everything from the electrical systems to the waterproof seals on the windows.

Chery may have duplicated Western practices in its plant, but it has an advantage on its American rivals in the cost of labor. Assembly line workers, such as the man at left, earn an average of slightly more than $1 an hour -- a sought-after wage in the poor province of Anhui 安徽.

Source:

http://online.wsj.com/article/SB119671314593812115.html?mod=yahoo_hs&ru=yahoo

The Wall Street Journal was allowed behind the scenes at Chinese automaker Chery 奇瑞, a rare privilege in China. The reporter didn't discover any top-secret plans for world domination or even a rendering of what Dodge's Chery-made car would look like. But he did see German and Italian robotics being used on production lines staffed by $1-an-hour workers 16 hours a day. It's a combination the story says should be good for global success.

In Chery's research center, engineers are developing 40-50 new models and the company is building a new production line capable of turning out 700,000 cars a year.

Chery chairman Yin Tongyao says they hope their relationship with Chrysler will allow Chery to hone its cars and streamline its production process. "People look down on our products. There are many doubts about our safety and quality," says Yin says in the WSJ piece. "If we work together with Chrysler, we can go global faster."

This year, it expects to sell more than 400,000 compacts, SUVs and sedans, such as these being prepped for assembly earlier this month at the company's sprawling production complex in Wuhu 芜湖, in east-central China.

This summer, Chery signed a deal to make cars for sale under Chrysler's Dodge brand -- the first time one of Detroit's Big Three has outsourced the production of entire vehicles to a Chinese company. At left, workers on the assembly line in Wuhu.

Tom LaSorda, president and vice chairman of Chrysler, says a visit to Chery's factories in 2006 convinced him the company's production was up to snuff. "Everything was very familiar," he says.

The Wuhu plant, like nearly all mass-production factories, relies on the assembly line, first developed in Detroit in the early 1900s by Ford Motor Co. founder Henry Ford.

Chery has hastened its growth by relying on Western technology, such as the Italian-made robots, left, that it uses to assemble its engines in Wuhu.

The engine plant also has German-made precision-milling machines.

The plant's paint shop is a turn-key project, ordered in one piece from a manufacturer in Germany.

The paint process involves dipping the entire car nose-first in a giant vat.

After the paint has dried, the finish gets a close inspection.

Near the end of the assembly line, the cars get a fill-up.

Last stop: A quality check, looking at everything from the electrical systems to the waterproof seals on the windows.

Chery may have duplicated Western practices in its plant, but it has an advantage on its American rivals in the cost of labor. Assembly line workers, such as the man at left, earn an average of slightly more than $1 an hour -- a sought-after wage in the poor province of Anhui 安徽.

Source:

http://online.wsj.com/article/SB119671314593812115.html?mod=yahoo_hs&ru=yahoo