Apart from seating position and vehicle condition, forward visibility plays a crucial role in driving; be it in daily commute to your office, weekend drives or in competition. It becomes even more critical when weather conditions come into play.

When the clouds turn grey and begin to pour what it has collected, the 2-piece device on your windshield is the only thing that can help you maintain forward visibility. With that said, a decent quality set of wiper blades will ensure optimum performance over time.

For years, conventional wiper blades constructed out of metal frames have been the standard. However, this metal frame design has a drawback – a worn out one is unable to effectively distribute pressure along the blade – leaving tiny (but disturbing) water strips or shades on the windscreen when it wipes.

To counter this issue, Bosch introduced flat-blade wipers. Developed in 1999, these wiper blades gets bracketless design with the purpose of distributing even pressure along the entire blade. The company believes that better wiping performance can reduce the risk of road accidents as 70% of the time, it occurs due to bad visibility.

<dl id="attachment_94759" class="wp-caption alignnone" style="width: 700px;" data-mce-style="width: 700px;"><dt class="wp-caption-dt">

Currently, 90% of new cars in Europe are factory-equipped with Bosch’s flat-blade wipers, and the percentage is steadily growing in Japan carmakers.

‘Made in Bosch’: Behind-the-scenes of how the flat-blade wiper is produced

The Bosch manufacturing plant in Changsha, China echoes the same manufacturing standards, equipment and processes of Bosch’s lead automotive plant for wipers in Tienen, Belgium. Spanning 82,000 square meters, the Changsha plant currently employs 4,640 associates.

A group of journalists from Malaysia, Indonesia, Thailand and Australia were invited by Bosch for an exclusive media tour around the manufacturing facility, which according to Bosch, was their first of its kind. So, we were kind of honoured to be one of the first.

Prior to the plant tour, we were gathered in a conference room for an introductory speech by Ms Wang Yufeng, Director of Sales and Marketing Services for Bosch Automotive Aftermarket in Asia Pacific Southeast.

According to Yufeng, they expect the trend of adopting flat-blade wipers into OEM (original equipment manufacturer) in Europe and Japan to reach Asia in the next few years.

“Having invested approximately 9 million Euros since 2004 in research and development efforts, Bosch stresses on robust design, reliable quality and superior service level as the focal points that are concentrated to win and maintain customers’ trust,” said Dr Norman Roth, Regional President for Bosch Electrical Drives of Asia Pacific.

He added, “All of our products come with a tagline ‘Made in Bosch’ as we implement the same manufacturing standards and quality control, regardless of the location of the plant.”

A windshield wiper is basically constructed from 4 different parts, namely the motor, linkage, arm and blade. During the plant tour, we were brought to the blade manufacturing and assembly facility. We could observe that the blade rubber is manufactured using high precision machinery to ensure low tolerance from output defects, before being assembled to its blade holder.

At another station, a group of operators install the newly-produced wiper blade to a wiper arm, mounted on a dummy windscreen complete with rain simulation. Every piece of wiper blade is tested and their wiping performance is evaluated based on a standardized marking scheme. Only blades that score 8 and above will become the actual production output. This process is done by a human operator as the observation cannot be performed by machine.

To further maintain the high standard of quality control, apart from quality audit done internally, Bosch also collaborate with lead partners to organize external quality evaluation so that the company can get a four-eye point-of-view on that matter, thus obtaining relevant quality certifications and ISO awards.

We also visited the research and development facility which spans about 2,400 square meters. At one of the labs, we witnessed how new wiper blades or prototype were tested.

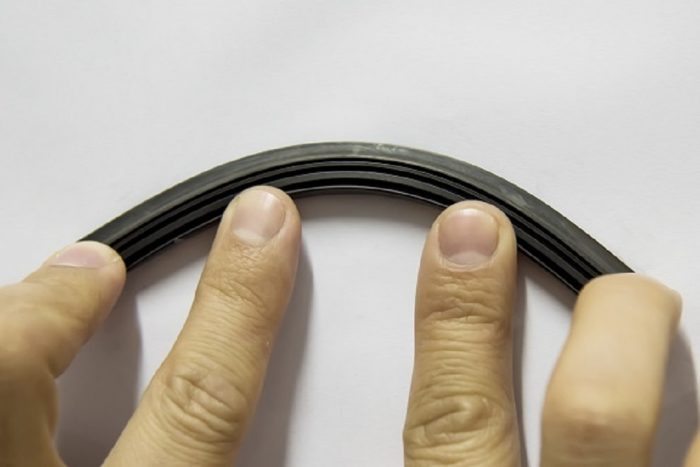

As an engineer demonstrates, the Bosch flat-blade wiper that has undergone several thousand wiping cycles perform very differently compared to a normal wiper blade in the same condition. Each of Bosch’s flat-blade wiper is designed to perform as new, even after 200,000 wiping cycles.

Bosch safety campaign: ‘One Wrong Part Ruins Everything’

Launched earlier this year, Bosch’s Automotive Aftermarket’s ‘One Wrong Part Ruins Everything’ campaign advocates safe driving with quality and reliable car parts in Asia. Ms Yufeng highlighted that the company would like to give awareness to the public on the importance of placing quality above price in their selection of aftermarket parts.

Bosch flat-blade wipers are now available on e-commerce platforms such as Lazada for countries like Malaysia (www.lazada.com.my/bosch-automotive-aftermarket), Singapore, Philippines, Indonesia and Thailand and Bosch Automotive Shop for Australia. The new Bosch Clear Advantage flat-blade wiper is retailed at RM65 a pair on Lazada and major car accessory shops. It is also available through Bosch authorized dealers in Asia.

For more information, visit www.startwithbosch.com.

Last edited: