- Jul 19, 2006

- 779

- 96

- 1,528

owh...noted.

the sounds becomes visible because i did raise the rear absorber a bit last week...gatal tgn lol...

the sounds becomes visible because i did raise the rear absorber a bit last week...gatal tgn lol...

yup...mine only hilo setting...cos im afraid the myvi & viva spring rebound is different

hence if the rear is raised abit, the spring could jump from its orignal position,

the only way is to keep it low...your only got hilo only no soft hard rite?

ic...thanx.try to set back to low 1st bro..c got noise anot....if yes, then could be the spring rate...

u need to find longer ones though.

Your car lowered very low? What car do you drive? Did you change the drive shafts, ARB link, bump stops etc to match the lowered height?dear car enthusiasts, need some explanation,

i drove out my car from car park which was a steep slope, even i tried to escape thru sideways, still i wrecked my front bumper causing maximum pressure on my front left tire and suspension, now i hear a squeeze sound (front left side) everytime i go over a speed bump,

can someone tell me what could be the reason?

hope u guys can help me, thanks

GAB HE SERIES

dear car enthusiasts, need some explanation,

i drove out my car from car park which was a steep slope, even i tried to escape thru sideways, still i wrecked my front bumper causing maximum pressure on my front left tire and suspension, now i hear a squeeze sound (front left side) everytime i go over a speed bump,

can someone tell me what could be the reason?

hope u guys can help me, thanks

GAB HE SERIES

thanks izso, its height is 2 finger gap between tire and fender with 15" inch rims, satria neo,Your car lowered very low? What car do you drive? Did you change the drive shafts, ARB link, bump stops etc to match the lowered height?

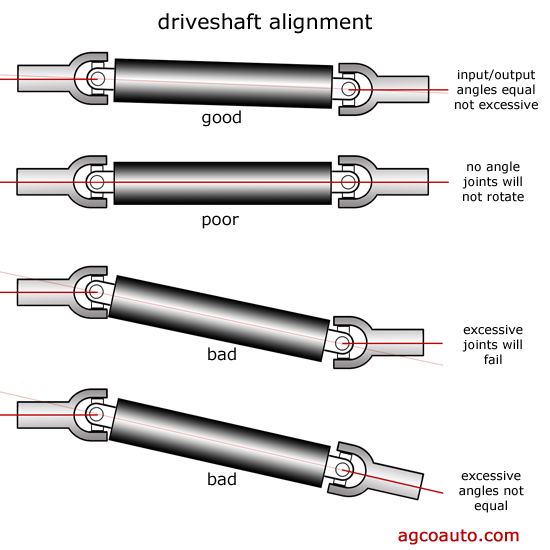

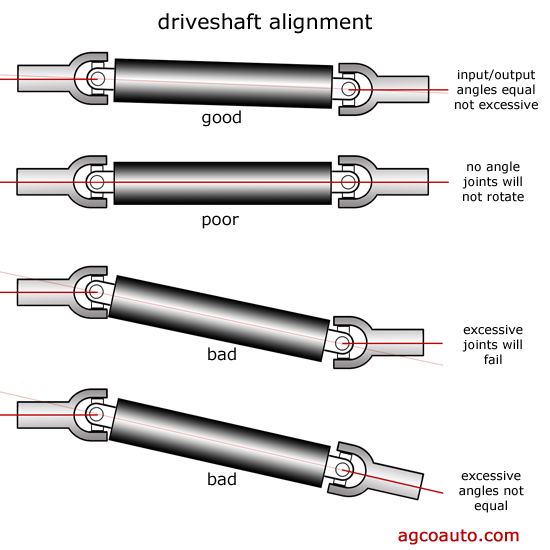

I don't know how to explain it technically speaking but maybe this picture can explain it :thanks izso, its height is 2 finger gap between tire and fender with 15" inch rims, satria neo,

yes, went to tire shop, they replaced the ball joint and ARB link,

even solved, appreciate if you can explain the relation with bump stops that match with lowered height, also the relation with driveshafts as i find its a bit harder to steer the right side compared to left side. Tq

thanks pal, that helped me getting a picture of it, what would be your suggestion after lowering the car? is it better to change some related parts that is performance oriented or remain stock parts?I don't know how to explain it technically speaking but maybe this picture can explain it :

Lowering the car will change the driveshaft angle and lots of other things will get affected too like ARB angle due to the linkages.

What people do is change to adjustable ARB links to cater for the lower height, adjustable arms (if they have any for your car) to adjust the geometry to cater for the height and that's kinda it. Lowering the car can be a pain in the ass if not done properly. But your height of 2-fingers thereabouts isn't too extreme so apart from the ARB link, I don't think you need to do anything else.thanks pal, that helped me getting a picture of it, what would be your suggestion after lowering the car? is it better to change some related parts that is performance oriented or remain stock parts?