Just pm me the name of his workshop or post here and I'll drop by his place and have a look.

If he's an online person, then all the more easier for discussion purposes.

Posting is quite an old method, I think you can read the history of it when you search the net.

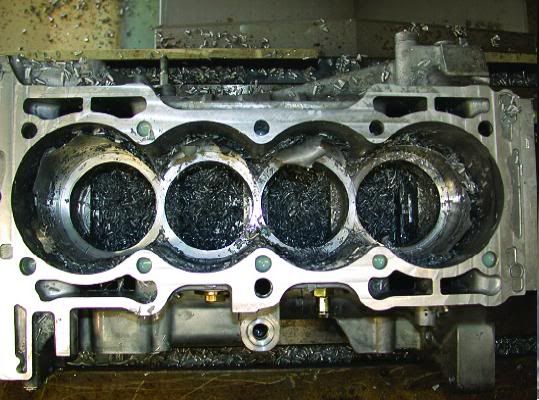

The strange thing, after visiting and looking at a lot of built engines in Malaysia, I've yet to see one posted. Usually it's the block guard.instead of posting

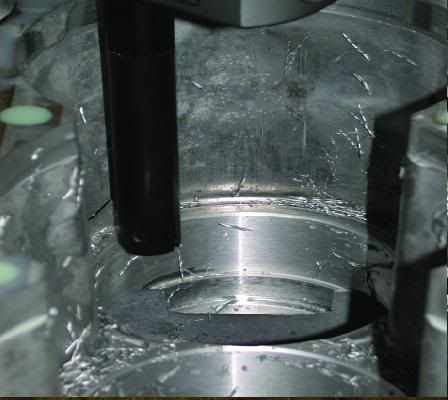

I understand that the primary concern to address by posting / sleeving is from the sleeves moving inside the block. due to the high rod stroke ratio run as we go up in terms of stroke, which give higher sidewall loading to the pistons and sleeves.

As for the your questions on sleeved, I've seen locally pressed sleeves, though I'm not sure how they perform.

I've seen a couple of Golden Eagle sleeves (the Godzilla range) and it's amazing how much abuse they can take. In fact, one engine actually ingested something and the sleeves managed to survive with minor scratches (rebored bigger to remove said scratches, even though the forged piston did have the hole the size of a 50sen coin.

One thing about sleeving though, is that there's always the risk of getting a coolant leak due to the sleeving process. (the process you mentioned is correct)

That's why if there's a shop that does posting, I'd like to know if it's successful as well. Personally I like the idea of posting because it's less risky (not to mention it does not inhibit coolant flow around the top of the block deck like what a block guard does, the area thatprobably sees the most heat, though I'm not even sure if the block guard can act as a heat transfer material, negating that effect so that's up for debate), so even though posting may never stand up to the abuse like sleeved units, it is another method compared to using block guards but when no one in Malaysia (as I thought before) uses the posting method, I thought that there must be inherent problem in getting it done right/properly.

That's why when you mentioned that there's someone doing posting, I'd like to see his work as well.

any other suggestion to strengthen b20b?

any other suggestion to strengthen b20b? I actually thought of importing Darton sleeves and some pistons from US but... hassle and all kinds of concerns and what else other the money involved in the job (Sleeves and pistons are cheap though!)

I actually thought of importing Darton sleeves and some pistons from US but... hassle and all kinds of concerns and what else other the money involved in the job (Sleeves and pistons are cheap though!)