who am i to say its +/- 0.1 because it depends on how accurate are your measuring devices. Even measuring cylinders are like +/-0.2cc tolerance, unless you're measuring using a calibrated weighing balance with accuracy of up to +/- 0.0001 which i doubt you'll have and that has to take into account a few other factors affecting accuracy. It actually depends on how accurate you want it to be which to me is not that important. Off the shelf, this two head flows slightly better than b16a head, thats about it.

But yes, i get your point though. Yes I do know it has a high impact on compression. Not only that, how about the deck height and milling involve, headgasket thickeness which may vary depending on torque applied. Thats why the zeal's and c-speedracing calculators are developed as a guide only and i would use that coz its pretty decent.

That's why I mentioned averages, and if the reading is off, the measurement is retaken again, because I do realise the potential errors inherent in the method.

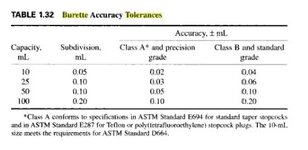

Actually I used a burette, and that is probably very close to +/- 0.1cc tolerance, since the minor scale is already around 0.1cc.

Actually compression calculation has one inherent flaw in that the gasket holes aren't exactly round, and at thicknesses of 1mm and below after torquing, that is one error factor in the calculation, hence other measurements must be as accurate as possible to reduce errors in the calculation. It's not going to be dead on accurate but it will be close.

In the end, the reason why I stress on this is because the heads that are in the market are

USED, and some are likely to have been milled before, and when STACKED together with other variables like boost/higher comp pistons, single layer metal gasket, etc. it can be a whole different thing than what was planned out, so relying on calculators is not really a good thing. Heck, I use them too, but I try to check them first, hence the reason I tested mine.

Of course, I do know that some modders

don't plan their build in detail, and obviously this doesn't apply to them, and guesstimating the SCR is good enough. The engine will work, and everything will be okay. Since I tune my own ride, I prefer to know details so I can see how it affects my tune in general, and if that change can result in more power. (with a 1.6NA, the gains are USUALLY

laughably marginal, compared to a 2.1 litre and up)

And there's also the thing I've heard about EK9 heads having bigger combustion chamber volume, so for boosted setups, it's possible that having an EK9 head would be better (and cheaper, if starting from scratch) than opting for a cometic gasket or other 'compression reducing' alternatives.

And if that factor isn't bothered with, why bother even finding out the final static compression? because piston ring sealing will dictate how well that compression is used, and also the cam durations, of course.

It's all about knowing enough about the engine to make it easy to tune, and realizing it's limits, and also, in a way, the fun of building engines, nothing more..

Some people obviously feel very fun buying crate engines from JUN, Spoon, etc. and those practically drop in to the engine bay and run.. but for those that prefer to make their own, knowing more about the engines they're building, or going to build is part of the fun.

.)

.) ) only to realize later that I can't measure H22A's without refilling because it's more than 50cc.

) only to realize later that I can't measure H22A's without refilling because it's more than 50cc.