Displayed at the recent Tokyo Auto Salon, This Epson Nakajima Racing cardboard GT car project is what every car guy should own. In a nutshell, it is based on a 1/24 scale replica of the GT car, the subject was photographed with a telephoto lens to decrease image distortion and then blown up to life-size. The image is then transferred onto cardboard ready for cutting. Skeletal sections of the car was also developed as a structural frame to house the body.

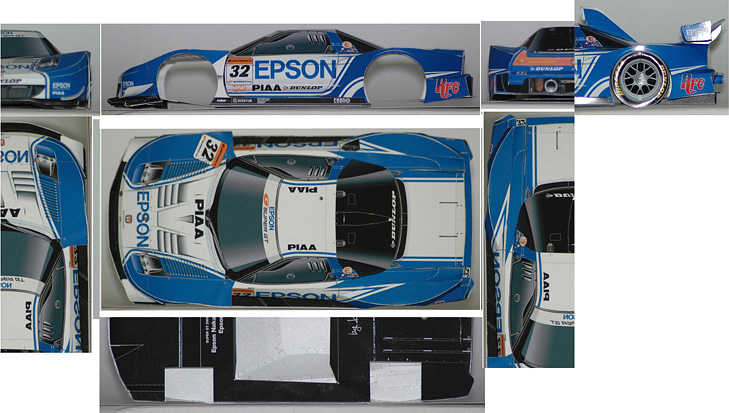

Photos of the 1/24 scale replica

Processed images of the car transferred to a working sheet.

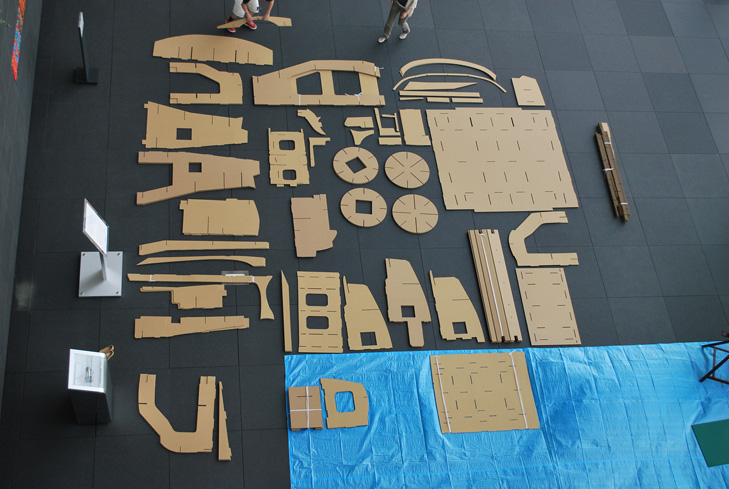

The cardboard framework was cut and and organized

Skeletal framework. Which was familiarly slotted together much like the usual hobby cardboard art.

Glue the pieces together

Lay on the skin. Glue.

Carefully glue Tab A to tab A1

Repeat steps. Check out the cardboard body coming to life!

Make sure the wheel fits.

Then mount the “hub” and reattached “finished” wheel.

What an Art-piece for the garage!

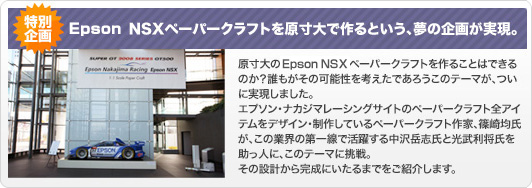

Original Source: (Japanese Translated)

http://www.epson.jp/nakajima/special/realsize_nsx/index.htm

“Kind of the same size as the NSX or Can not create paper craft” of this project was the first contact from Mr. Shinozaki and Epson, in March 2008 SUPER GT was the presentation of the team structure. Shinozaki’s production-proven in a large cardboard Kraft said, “OK do it also put a large cardboard frame what size, can make” a little lighter and would reply. Then the three summer months, the project officially determined, he began working on the design Shinozaki.

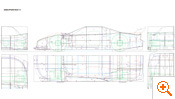

The first 1 / 24 scale and modify the deployment diagram, you create a full-scale deployment diagram. Until there was a fine, and serve as a life-size, bonded paper just so I can not support the shape of the inner frame to provide a framework, the paste from the top to match the need to maintain the shape of the was. How can we design a precise framework do it? There should be no such three-dimensional shape measuring instruments. After all, 1 / 24 was the only way to measure the shape of Sukerupepamoderu analog. All you need to design, the detail is making more accurate drawing of 4.

First, 1 / 24 Sukerupepamoderu taken, using a telephoto lens to avoid distortion of the lens as much as possible. Capture data to your PC, you have taken to correct the distortions that will fit the actual dimension. If you design a problem based on this framework is not cardboard. Then prayed together and God will work out in the field. Using the framework of corrugated and kraft paper, so if full-scale, because the intention was only仕上Getai paper. Skeleton-like and the weight of our own because there is just cardboard, no effect on the strength part is gouged out, the measures taken by the same way like lighter vehicle. Exploded even 1 / 24 some parts are more divided than was devised so easily bonded. 3 If the framework is in place I can design Sun, it has taken more than 10 days. So far spent a total of two weeks.

|

|

|

| 1 / 24 of the Craft 4 Photos Surface | Plan of the skeleton frame of | Exploded in the skeleton frame |

|

|

|

| Exploded in the skeleton frame | Exploded View full size print | Exploded View full size print |

Exploded frame and made it, and gone to print without processing each of the seven began in Nagano Epusoninobeshonsentahoru assembly and finally completed at the end of it. The production shifts to cheer me Kaketsuke Mitsutake Mr. Kraft and his fellow Nakazawa. Making it part of the foundation and framework first. Bonded or processed without the cardboard, and robust framework will then be combined. The figure also notes that the deployment order form a bone. And order the wrong partner, it will be ridiculous later.

One big one because different parts of the traditional paper craft and become even larger natural tool to use. Laminated wood used to bond a wide area in particular, raised the efficiency by a large container into a paint roller. You need the strength of the frame and in addition, were used in the manner of hot-melt adhesives can be soldered. A tool is changed, and scoring a whopping “pizza cutter” is used.

Thus part of the rear cabin, the front shaft and went in order to produce tires. The skeleton frame assembly operations, but had assumed much of the day happens to ease the expected. The second day was just one part of the cabin. Rear, front, remaining until the completion of the shaft of the tire was taken one day.

| Cut | Scissors Cutters |

|---|---|

| Fold | Fri Bella Pizza Cutter |

| Put | Strong double-sided tape hot melt synthetic rubber adhesive glue |

|

|

|

| Part cardboard check | Paste the roller parts | Assembly of the frame body |

|

|

|

| Tire shaft assembly | Being assembled front body frame | Almost completed during the entire frame |

Produced the third day, the skeletal frame of a real car-like chassis finally finished, cut the figure printed deployment, we went to work finally bonded. The print width 1200mm, length 2300mm Exploded huge total of 25 sheets, see Part 126. Stuck behind the car rear diffuser portion of the framework first. Finally finished the 60 to 70kg in weight because they are expected to be, so I can not afford to keep doing it later in the first turn, it does not work the first time.

For other parts, as well as cut, do not sacrifice is not embedded. Only paper that is printed, even in much the frame, when strength is bonded endlessly. Exploded is so thick on the back of one side of 3mm put a cardboard “backing” he called the work required. Exploded back of the seal has already been processed, we carefully put the cardboard to avoid the slack there. Flute cardboard and bend the parts when the direction (of the type that the mountain wave) becomes difficult because then you do not do the same bending direction, taking into account the work goes on steadily. Shinozaki She says, “Tired and just continue doing it.” Nevertheless, she continued to work hard all day to cut corners and made a significant impact here.

|

|

|

| Figure printed enormous expansion | Diffuser section completed | Bottom laminated body |

|

|

|

| Cut begins | Crop still continues | Cardboard backing to one side |

Frame starting from the fourth day of the month end 8 in the process of laminating and earnest. Exploded parts finely cut lined street, go over the skeletal frame from being bonded. Ride around the framework to show off parts from the rear window over the front window first. Completed the top of each cabin is also bonded. Because this portion of the frame can be put after being bonded, can also bonded fine. Most of the upper body is now backed by the cardboard piece to give the exterior tension of the paper. Processing has been added to make it easier to stabilize when carrying parts in addition to the skeletal frame. Thus hood, rear hood work well cut and go in the summer was ending.

|

|

|

| Skeletal framework of coordination | In addition to the back lined roof | Of the laminated window |

|

|

|

| Flute peel adhesion surface | So check in from within the framework | Steady work is far from over |

Fall season was also quite the end of May 9, five day work. Be elusive entered from each side bonded parts such as fenders and doors around. When bonded to the upper part and side parts of the car, 1 / 24, the paste can be combined from both front and back flip if, in the full scale does not even have it. Be limited for a place to put a framework on the inside of the car yet. He was required to continue to work together to carefully consider the order so paste. And the legs of the mirror just because it needs to support the weight of the body mirror, it becomes necessary to work within the framework of fixed pre-inserted. Three parts overlap more and more quadrics, 1 / 24 scale have come to the distortion and misalignment of non-bonded. Tame Naka scratch the frame or frame that was also necessary to adjust or supplement. Bonded parts each time, peel the release agent once, followed by a match for fine paste in plain again.

|

|

|

| Rear panel bonded | Paste the rear cover | Door of paste |

|

|

|

| Laminated tire work | Check the tire mounting | Bonded around the front |

In October, production was finally entering the final stage. Completion around the body to some extent in the process of fine tuning. Hagarenai rear wing is fixed to the frame parts in the hot-melt, had completed the wing veneer bonded to the end. Mounting the unit had trouble mounting the mirror leg, make sure you do not lean on weight. Air intake is fixed at the top of the roof also had trouble. Inserted from the top is just above the rear because they floated with the situation, but I want to fix from within, the borders of an obstacle course. Add Shinozaki’s somehow still find a place was fixed in the intake system but painful. Thus from the first assembly 10. EPSON NSX finally completed the full size.

|

|

|

| Replacing the wing | During the hot-melt adhesive paste frame | Floating air intakes from roof |

|

|

|

| Replacing the body of the mirror | Handling of cross-sectional cut | Adjust tire mounting |

■ After the production’s Shinozaki Hitoshi

Honestly, was tougher than I thought. It took time and much higher than originally planned. Work itself, 1 / 24 and does not think such problems occurred. We do not work properly during the bonding making the order, or where there is no holding from behind. Its minutes, but the sense of accomplishment when we are great. Mitsutake’s there and who helped to produce Nakazawa is great. Epson says you have the opportunity to produce and are grateful.

http://www.epson.jp/nakajima/special/realsize_nsx/index.htm