New Project - Chasis Stiffening Mods for Improved Handling

- Thread starter defcon1

- Start date

- May 26, 2006

- 775

- 2

- 1,518

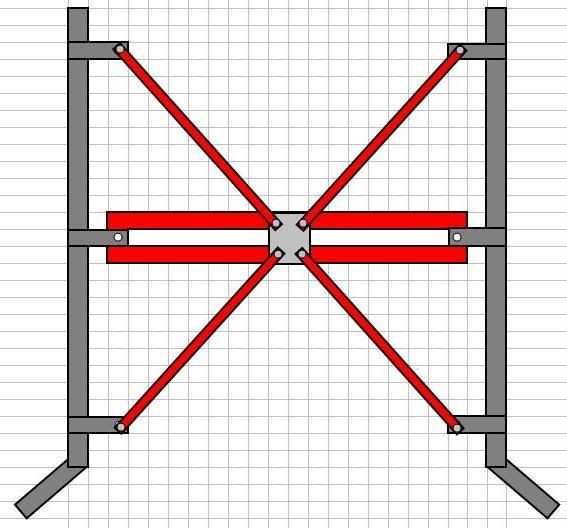

Subframe Connectors - basic design by defcon1 for the 1996-1999 Nissan Cefiro.

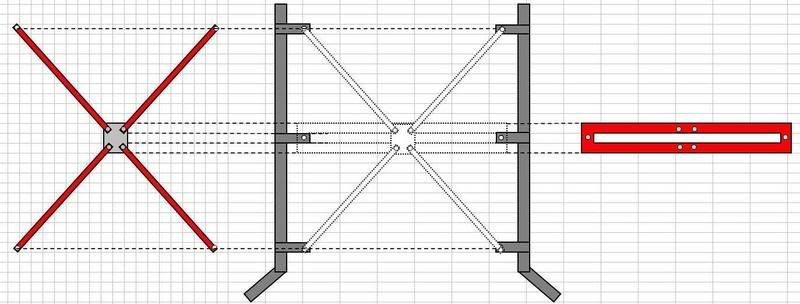

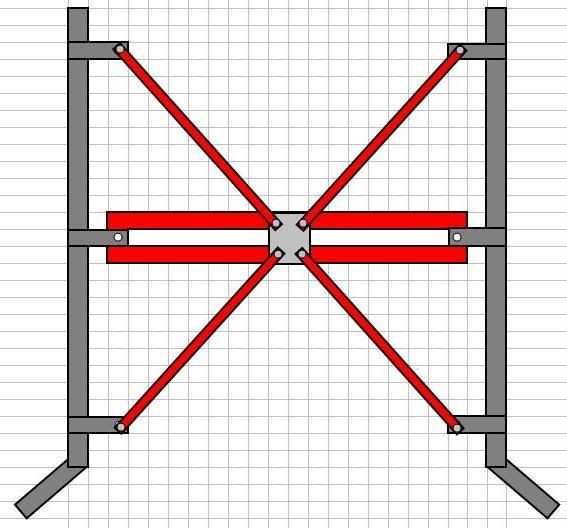

Components of the Subframe Connector :

The completed structure :

The diagrams are, of course, not to scale. But I should be doing some basic measurements this weekend so that I can complete the schematic and get someone to begin fabrication...

Components of the Subframe Connector :

The completed structure :

The diagrams are, of course, not to scale. But I should be doing some basic measurements this weekend so that I can complete the schematic and get someone to begin fabrication...

- May 26, 2006

- 775

- 2

- 1,518

The subframe connector prototype is being built. Lee's bro is a machinist and welder...

Next week, we'll do the measurements and the final re-design. I have to take a few more things into consideration i.e. is the original rail strong enough to take the force. If not, the design will be modified to spread the force a little more and not just to the 6 welding points. I've also been under the car and come up with a little tweak that will improve the overall handling...

Both the front end and rear end of the rails will connect via a very strong bracket to the bolts holding the lower arm in front and the torsion bar in the rear. This will eliminate, to a greater degree, the flexing especially of the front absorber mounts during hard turns and hard braking.

Also, I am considering machining some simple bushings out of nylon or hard polyurethane to give the entrie subframe connector a very little bit of flex...basically allowing some of the force to spread over a larger area...

Let's see what finally comes out...

p.s. when deffy says he's building it....he BUILDS it...

b)

Next week, we'll do the measurements and the final re-design. I have to take a few more things into consideration i.e. is the original rail strong enough to take the force. If not, the design will be modified to spread the force a little more and not just to the 6 welding points. I've also been under the car and come up with a little tweak that will improve the overall handling...

Both the front end and rear end of the rails will connect via a very strong bracket to the bolts holding the lower arm in front and the torsion bar in the rear. This will eliminate, to a greater degree, the flexing especially of the front absorber mounts during hard turns and hard braking.

Also, I am considering machining some simple bushings out of nylon or hard polyurethane to give the entrie subframe connector a very little bit of flex...basically allowing some of the force to spread over a larger area...

Let's see what finally comes out...

p.s. when deffy says he's building it....he BUILDS it...

b)

- May 26, 2006

- 775

- 2

- 1,518

heh...all hidden mods...

Not sure...depends on next week...whether we can solve all the structural problems we will encounter...

We need to put in the mod, with minimal damage to the original chasis...and spread out the force enough such that the attachment points of the subframe connectors do not become stress points and cause the chasis to break...

Not sure...depends on next week...whether we can solve all the structural problems we will encounter...

We need to put in the mod, with minimal damage to the original chasis...and spread out the force enough such that the attachment points of the subframe connectors do not become stress points and cause the chasis to break...

chris...pls share some photos if u manage to get it...cant wait for the result. whats the expected costing?

- May 26, 2006

- 775

- 2

- 1,518

Ultra Racing's costing for a stage 1 perdana is around RM 450 - 550. This is a stage 2, but because it's so easy to build, I do not expect to hit UR's price.

Keep in mind...this mod basically makes upgraded anti-roll bars and rear sway bars redundant for normal driving. In track cars, these 2 bars still need upgrading.

Keep in mind...this mod basically makes upgraded anti-roll bars and rear sway bars redundant for normal driving. In track cars, these 2 bars still need upgrading.

- May 26, 2006

- 775

- 2

- 1,518

Rear pillar strut bar is available from hotbits...not very expensive...

Front pillar strut bar...never found any available in Malaysia...

I could design one for you....a basic 2 pt or a nice 3 pt, and you can get it made... :)

Front pillar strut bar...never found any available in Malaysia...

I could design one for you....a basic 2 pt or a nice 3 pt, and you can get it made... :)

- Mar 21, 2006

- 117

- 0

- 1,516

Would like to, but I actually saw 1 post which shows a pic of a UR's bar which broke at the end ... hmm ...ongteckweng said:why dont try UR or Zero One or hotbits..price might be higher though

SweetOr Lee's bro could make it for you...

Will be going back to Cameron this coming weekend, a somewhat improved handling will be a lot of help going up

- May 26, 2006

- 775

- 2

- 1,518

I think we've finally worked out the final technical details for the fabrication of this item.

After checking on the strength of the metal plate under the car, we've decided to spread out the force by welding on mounting plates i.e. metal plates cut to the exact width of the original rail, with a hole in the middle and a nut welded around the hole. These will be welded directly onto the rail, and corresponding with the holes already in the rail (these holes were put there by Nissan as measurement points in the event of chasis damage and repair), This will spread out the force over a much larger area and also make the connectors removable.

Another thing I am thinking of are polyurethane or nylon spacers where the connectors bolt to the rail. This will spread the force out even more, and allow a very little bit of flex, which, believe me, is important for handling because you don't want to drift every corner (an OVER stiffened chasis will do this). These spacers will also eliminate any squeaks or noises when the connectors are flexed.

AND...Lee's bro expressed an interest in my aluminium pillar strut bar. He can make them and is interested to do so. I'm actually thinking of developing more of these things...strut bars, anti-roll bars, rear sway bars, subframe connectors, branding them DEFCON1 and marketing them...

Heh...I'll definitely give UR a run for their money...

After checking on the strength of the metal plate under the car, we've decided to spread out the force by welding on mounting plates i.e. metal plates cut to the exact width of the original rail, with a hole in the middle and a nut welded around the hole. These will be welded directly onto the rail, and corresponding with the holes already in the rail (these holes were put there by Nissan as measurement points in the event of chasis damage and repair), This will spread out the force over a much larger area and also make the connectors removable.

Another thing I am thinking of are polyurethane or nylon spacers where the connectors bolt to the rail. This will spread the force out even more, and allow a very little bit of flex, which, believe me, is important for handling because you don't want to drift every corner (an OVER stiffened chasis will do this). These spacers will also eliminate any squeaks or noises when the connectors are flexed.

AND...Lee's bro expressed an interest in my aluminium pillar strut bar. He can make them and is interested to do so. I'm actually thinking of developing more of these things...strut bars, anti-roll bars, rear sway bars, subframe connectors, branding them DEFCON1 and marketing them...

Heh...I'll definitely give UR a run for their money...

wah...the market is gettin more n more players...I think we've finally worked out the final technical details for the fabrication of this item.

After checking on the strength of the metal plate under the car, we've decided to spread out the force by welding on mounting plates i.e. metal plates cut to the exact width of the original rail, with a hole in the middle and a nut welded around the hole. These will be welded directly onto the rail, and corresponding with the holes already in the rail (these holes were put there by Nissan as measurement points in the event of chasis damage and repair), This will spread out the force over a much larger area and also make the connectors removable.

Another thing I am thinking of are polyurethane or nylon spacers where the connectors bolt to the rail. This will spread the force out even more, and allow a very little bit of flex, which, believe me, is important for handling because you don't want to drift every corner (an OVER stiffened chasis will do this). These spacers will also eliminate any squeaks or noises when the connectors are flexed.

AND...Lee's bro expressed an interest in my aluminium pillar strut bar. He can make them and is interested to do so. I'm actually thinking of developing more of these things...strut bars, anti-roll bars, rear sway bars, subframe connectors, branding them DEFCON1 and marketing them...

Heh...I'll definitely give UR a run for their money...

- Dec 7, 2006

- 579

- 5

- 1,518

knn...can public listed liow n sell to NISSAN..hehehecertified by SIRIM (MY), TUV (GERMANY), QAS (AUSTRALIA) according to JIS ?????

- May 26, 2006

- 775

- 2

- 1,518

Why don't I public list and BUY Nissan....knn...can public listed liow n sell to NISSAN..hehehe

The Marketplace Latest

The Marketplace Top Posts

-

Top Secret Nissan R35 GTR GTR35

- Started by aycy

- Cars for sale

Recent Posts

-

Review: 2023 Toyota Vios 1.5G

- Started by Tom

- News and Features

-

Satria GTI or Normal Satria

- Started by deveshwhat

- Car Talk

-

Honda civic fd2 with k20z2 engine...

- Started by Soroosh-ab

- Honda

Random Post Every 5 Minutes

For Campro owners most will have faced this minor issue of oil leak at the top valve cover. This problem will start roughly around the 30,000KM plus mileage. If you are a slow driver and seldom rev the engine hard you can delay this problem until 60,000KM or so...when the oil leak happens it does not affect the engine performance but just becoming an eye sore and if go unattended the leak will start to worsen or other parts of the top cover will start to leak. This problem can be solved and...

Ask a question, start a discussion or post something for sale!

Post thread

Enjoying Zerotohundred?

Log-in for an ad-less experience