4AG BT with CP High comp piston.. compression 10?

- Thread starter mafia_staff

- Start date

- Replies 50

- Views 7K

what parts do you upgrade/use apart from the piston?

2mm head skim is too much, prone to detonation and rough idling...

or do post your a/f ratio graph since you've dynoed...

Acousti, a long time didnt see this type of post...

too many thing to think of la...:rolleyes:

btw, yes you're right...

once you upgrade your car power, you need to look at handling...

'dah bole handle'... then upgrade power some more.. then handling again...

2mm head skim is too much, prone to detonation and rough idling...

or do post your a/f ratio graph since you've dynoed...

Acousti, a long time didnt see this type of post...

too many thing to think of la...:rolleyes:

btw, yes you're right...

once you upgrade your car power, you need to look at handling...

'dah bole handle'... then upgrade power some more.. then handling again...

Last edited:

Doing the checking..

---------- Post added at 03:48 PM ---------- 6 hour anti-bump limit - Previous post was at 11:30 AM ----------

Kegani is not involve in this case.. Different shop for hardware, different person for dyno tuning

---------- Post added at 03:48 PM ---------- 6 hour anti-bump limit - Previous post was at 11:30 AM ----------

Kegani is not involve in this case.. Different shop for hardware, different person for dyno tuning

- Jul 10, 2004

- 987

- 62

- 3,028

Compression ratio (static) and results from compression test is not the same.You cant compare 10.5 compression ratio to 10 bar compression you get from compression test.

The stock compression pressure for blacktop is 13.8bar,some also call this dynamic compression (compression pressure that is,not ratio).If yours is 10 bar then there is something wrong.But the compression pressure is affected by a few thing,mainly cranking speed,cylinder sealing and cam duration and timing.To get good results,the cylinder must be as air tight as possible when the piston move up in compression stroke.

Now,when you fit a long duration cam,coupled with low cranking speed,some air will escape compared to the stock cam,because the cam opens the valve longer,so it is expected to go slightly lower if youre still using stock piston.But with hi comp piston,for it to go that low (13.8 down to 10) is weird.Long duration cams will work when the engine is running,when there is enough air speed coming in and out of the cylinders.

It could be a lot of factors.

I suggest you carefully check your cam timing,make sure it is DEGREED CORRECTLY,check your cam spec that the manufacturer suggested to have the cam fitted at how many degrees lobe center.When you use thin head gasket and also skimmed head,your cam timing will be wrong by a few degrees compared to stock,so please check.Check your valve clearance too,make sure its within the specified range.

I think your compression ratio would be good enough,its just that your compression pressure result is worrying.

About the Adaptronic,its a good ecu i dont think there is something wrong with it.

The stock compression pressure for blacktop is 13.8bar,some also call this dynamic compression (compression pressure that is,not ratio).If yours is 10 bar then there is something wrong.But the compression pressure is affected by a few thing,mainly cranking speed,cylinder sealing and cam duration and timing.To get good results,the cylinder must be as air tight as possible when the piston move up in compression stroke.

Now,when you fit a long duration cam,coupled with low cranking speed,some air will escape compared to the stock cam,because the cam opens the valve longer,so it is expected to go slightly lower if youre still using stock piston.But with hi comp piston,for it to go that low (13.8 down to 10) is weird.Long duration cams will work when the engine is running,when there is enough air speed coming in and out of the cylinders.

It could be a lot of factors.

I suggest you carefully check your cam timing,make sure it is DEGREED CORRECTLY,check your cam spec that the manufacturer suggested to have the cam fitted at how many degrees lobe center.When you use thin head gasket and also skimmed head,your cam timing will be wrong by a few degrees compared to stock,so please check.Check your valve clearance too,make sure its within the specified range.

I think your compression ratio would be good enough,its just that your compression pressure result is worrying.

About the Adaptronic,its a good ecu i dont think there is something wrong with it.

Last edited:

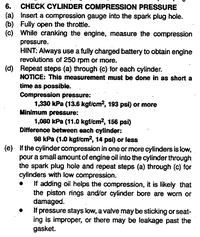

IMO, higher compression pistons and aftermarket cams doesn't necessary mean you'll get higher compression when doing compression checking through the spark plug hole. To do a proper compression testing, its more complicated. Checking compression through the spark plug hole is usually used to identify if there's any compression loss between the pistons mainly due to worn out compression rings. So a spark plug compression test is not the proper way to check for engine compression rating.

Anyways, attached below showing compression checking reference from 4AGE service manual. It says compression pressure 13.6kgf/cm² or more and minimum pressure 11.0kgf/cm².

Hope it helps to clear out the air.

Anyways, attached below showing compression checking reference from 4AGE service manual. It says compression pressure 13.6kgf/cm² or more and minimum pressure 11.0kgf/cm².

Hope it helps to clear out the air.

Attachments

-

123.1 KB Views: 90

Check.. Im using ron 95 and ron 97.. check already the engine, I think the metal gasket too thick.. Nothing wrong with the tuner.. My conclusion the mechanic just know to have a theory talk instead of experience working with high comp piston, stop pour money to drain again.. I'll go to another workshop instead.. :wavey:

i think the mech worry about the piston/valve clearance...

you need to check it if you use aftermarket high comp piston...

my mech normally do something to CP piston valve pocket...:hmmmm:

you need to check it if you use aftermarket high comp piston...

my mech normally do something to CP piston valve pocket...:hmmmm:

Problem identified... need to skim head and block.. thanks guys.. Mechanic admit his fault.. moral of the story- whatever you want to do, make sure you have knowledge or 'concept' what you should do.. adios

- Aug 5, 2004

- 1,840

- 547

- 3,213

Problem identified... need to skim head and block.. thanks guys.. Mechanic admit his fault.. moral of the story- whatever you want to do, make sure you have knowledge or 'concept' what you should do.. adios

skim head n block???? if ur doing this bcoz ur head gasket is too thick...then u should definitely change gasket instead of skim... that is an irreversible mod...remember that

Yea agree partially, skimming head and/block's purposes are to prevent loss of compression due to uneven surface on either or both the head and block aka to attain the optimum compression ratio. But I don't think u can get more compression from skimming either/both the head and block. Do correct me if I'm wrongusually people skim head bcoz of uneven surface

to get more compression ?

gudluck

.

.I have clearance between TDC and top level of head about 3mm, I don't know how this happen... and do you know what is the purpose metal head gasket? from my two cents knowledge metal head gasket is a variable to adjust the compression.. so I shave head and block and counter it with metal head gasket.. do correct me if I'm wrong..

how much to skimmed?

wierd coz 3mm clearance is too much coz you're using CP piston...

if i can remember; only skim max 0.5mm if using 0.8mm TRD gasket...

this is with Toyota 0.5mm oversize piston...

if more than 'engine tak sedap'...:hmmmm:

wierd coz 3mm clearance is too much coz you're using CP piston...

if i can remember; only skim max 0.5mm if using 0.8mm TRD gasket...

this is with Toyota 0.5mm oversize piston...

if more than 'engine tak sedap'...:hmmmm:

Last edited:

its been many years but 8 mm gasket??how much to skimmed?

wierd coz 3mm clearance is too much coz you're using CP piston...

if i can remember; only skim max 0.5mm if using 8.0mm TRD gasket...

this is with Toyota 0.5mm oversize piston...

if more than 'engine tak sedap'...:hmmmm:

Devil in the details...but are the CP pistons supposed to be paired with their rods.. check the pin location first..just my 2 cents mate...no experience with CP stuff or 3S engine!

---------- Post added at 11:56 AM ---------- 6 hour anti-bump limit - Previous post was at 11:25 AM ----------

Attached CP catalog

http://www.cp-carrillo.com/LinkClick.aspx?fileticket=yrZ5T5U6dHU%3d&tabid=82

The Marketplace Latest

The Marketplace Top Posts

-

Top Secret Nissan R35 GTR GTR35

- Started by aycy

- Cars for sale

Recent Posts

-

Review: 2023 Toyota Vios 1.5G

- Started by Tom

- News and Features

-

Satria GTI or Normal Satria

- Started by deveshwhat

- Car Talk

-

Honda civic fd2 with k20z2 engine...

- Started by Soroosh-ab

- Honda

Random Post Every 5 Minutes

Hi sifu I'm Ming Fai here.

Can u all share your experience to me with modify a Mitsubishi engine 4g91pls...

Can u all share your experience to me with modify a Mitsubishi engine 4g91pls...

Ask a question, start a discussion or post something for sale!

Post thread

Enjoying Zerotohundred?

Log-in for an ad-less experience