- Jun 4, 2006

- 2,798

- 334

- 1,683

Hi everyone. 2 weeks ago, I was hanging around my mechanic's place doing nothing better than sleeping, gossiping and talking CXCK and laughing laudly... Realizing my mechanic was busy dismentalling a CAMPRO 1.6 engine to overhaul, I decided to get my hands dirty and help him up...

As we were busy dismentalling the engine, we chat about CAMPRO 1.6 BOT failure on Crank and we realizeD BOT DOES NOT FAIL THE CAMPRO CRANK, BOT ONLY ACCELERATE THE FAILING PROCESS OF THE CRANK.

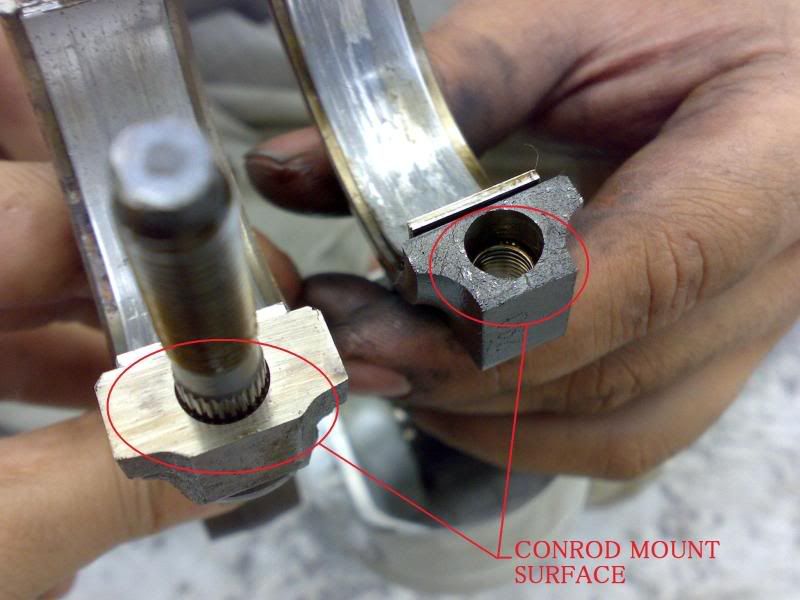

And we also realize that the cause of the Crank failure is actually from the CONROD. Here are some picture I've taken in comparison between a CAMPRO 1.6 CONROD vs a 4G92P CONROD.

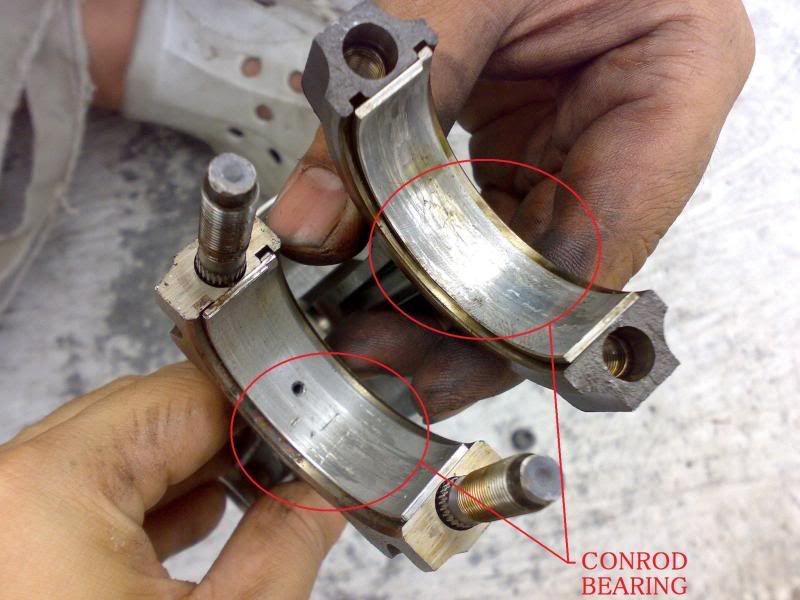

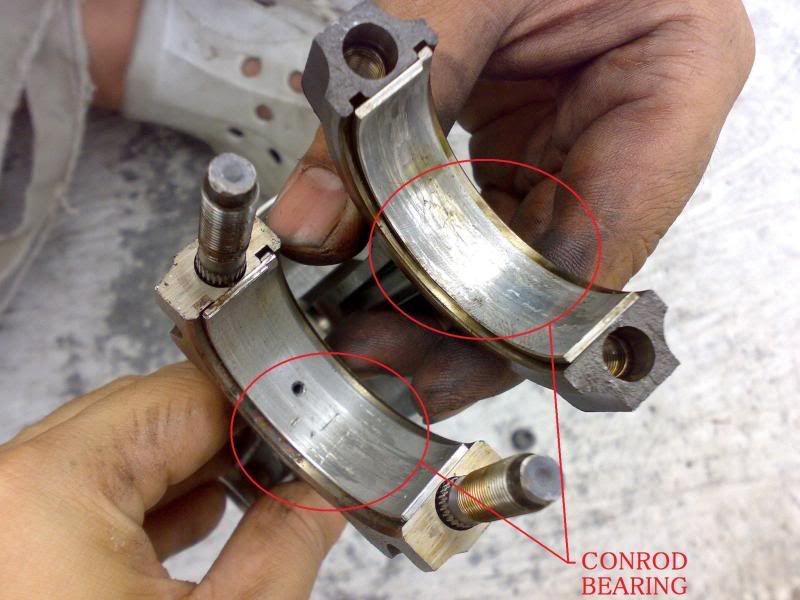

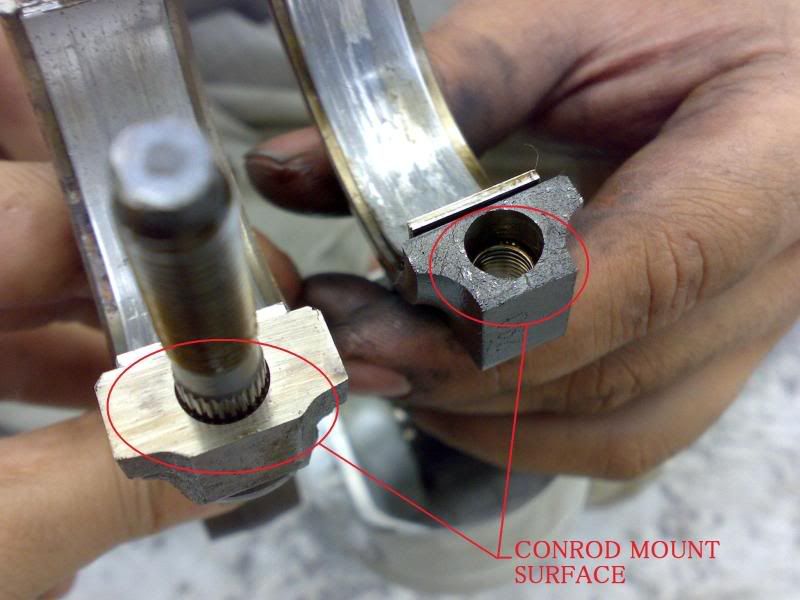

IMAGE 1

The holes are for the engine oil to enter the conrod bearing for lubrication and cooling furpose as the Crank is turning within the Conrod bearing. without sufficient lubrication, the crank will wear out the conrod brearing.

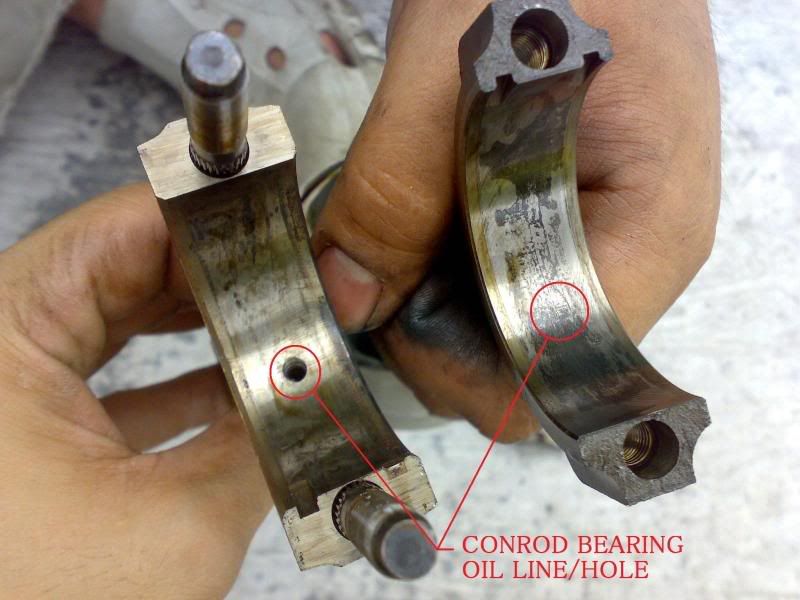

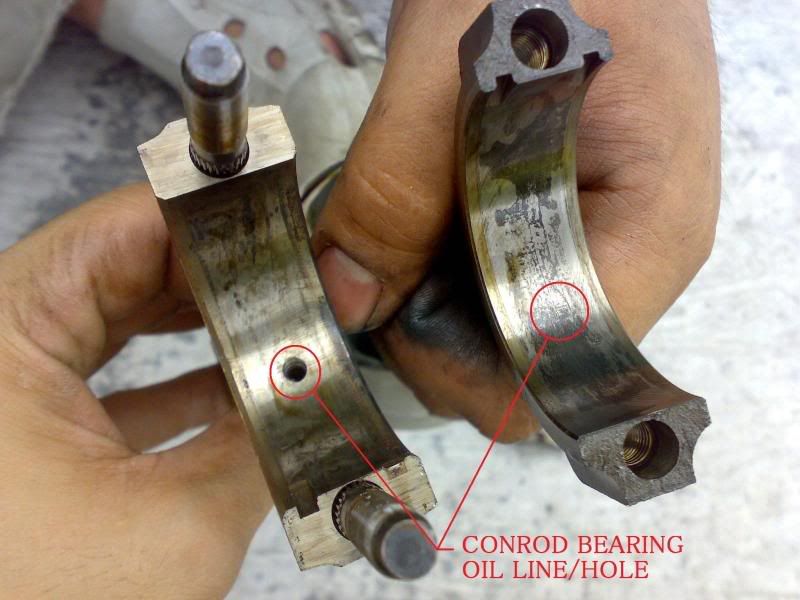

IMAGE 2

An Image showing the Conrods without the bearing.

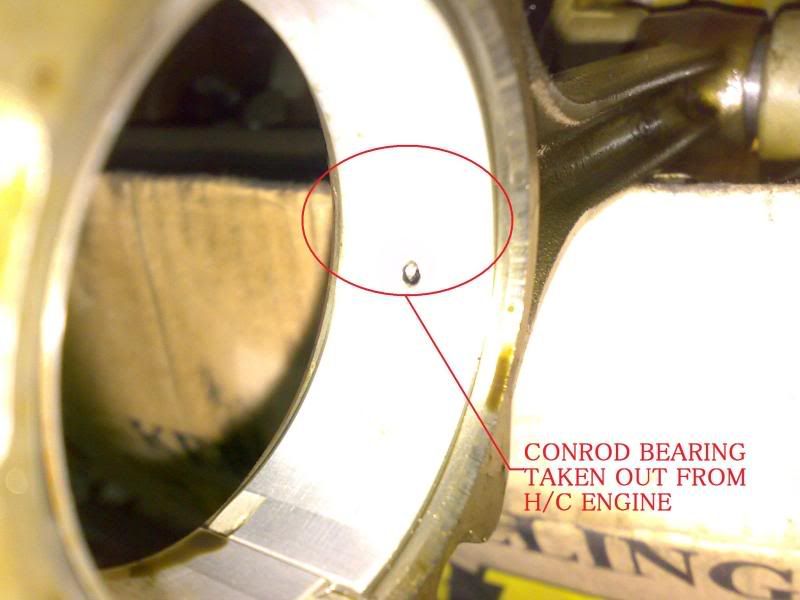

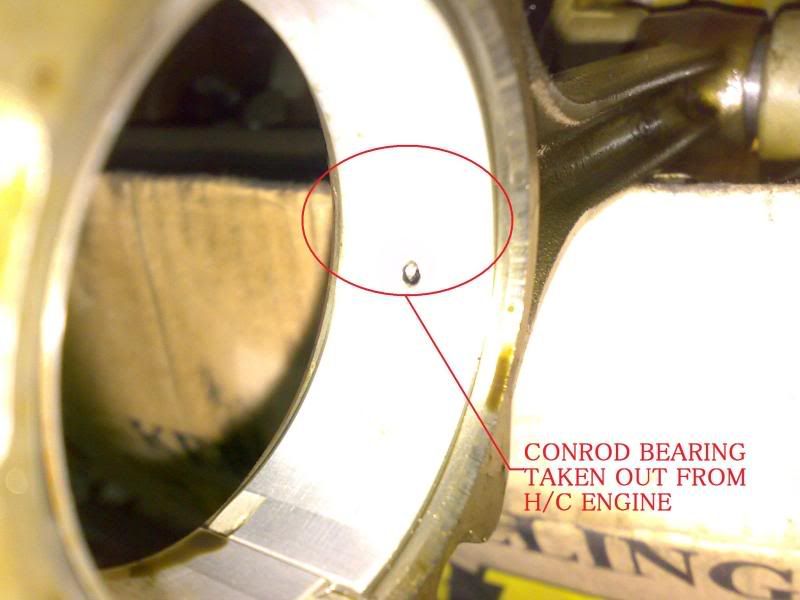

IMAGE 3

This is the CONROD Bearing used for around 100,000KM running all time on Semi Synthetic Oil. Owner claim he seldom gasak the engine. Realize that the bearing is ot smooth anymore. And sooner or later, it'll create higher friction to the cranks.

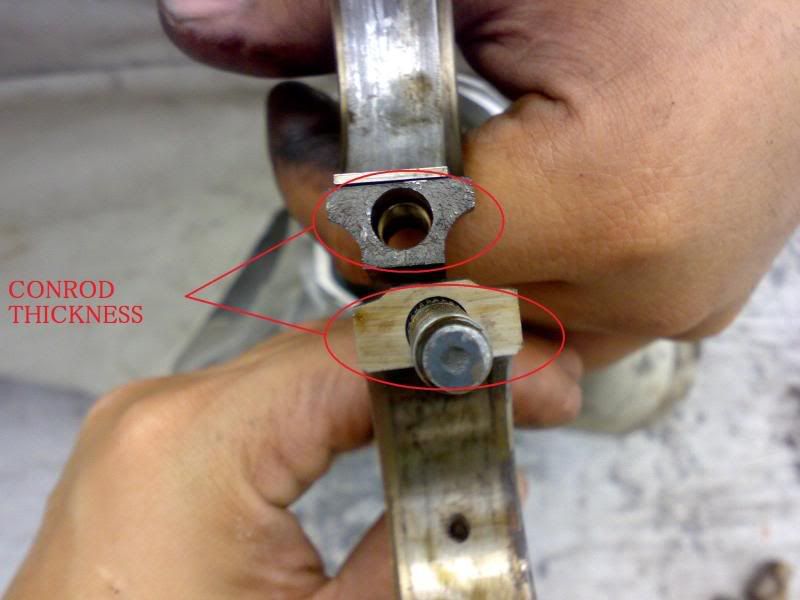

IMAGE 4

This is a CONROD BEARING from a 4G93 mitsu engine kosong from halfcut. Not sure about the date.

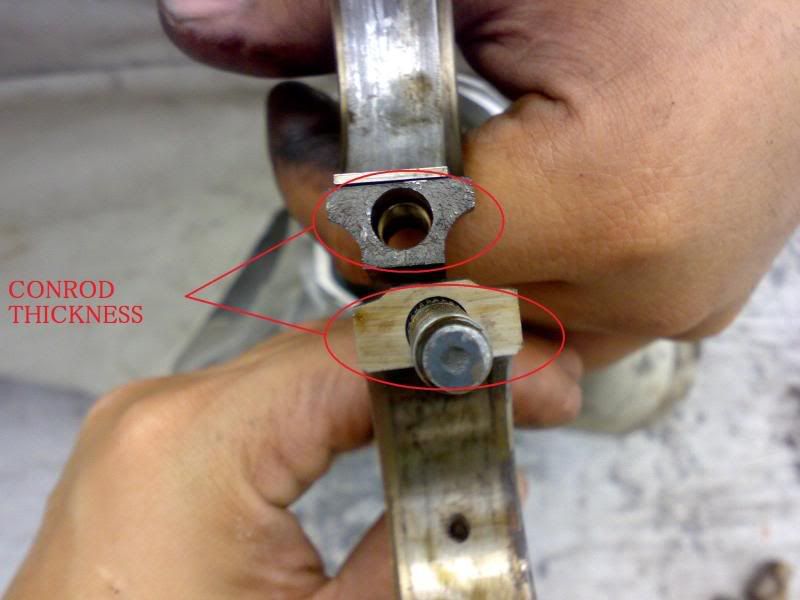

IMAGE 5

Take a look at the CONROD thickness comparison. Should voice anything else..? U judge.

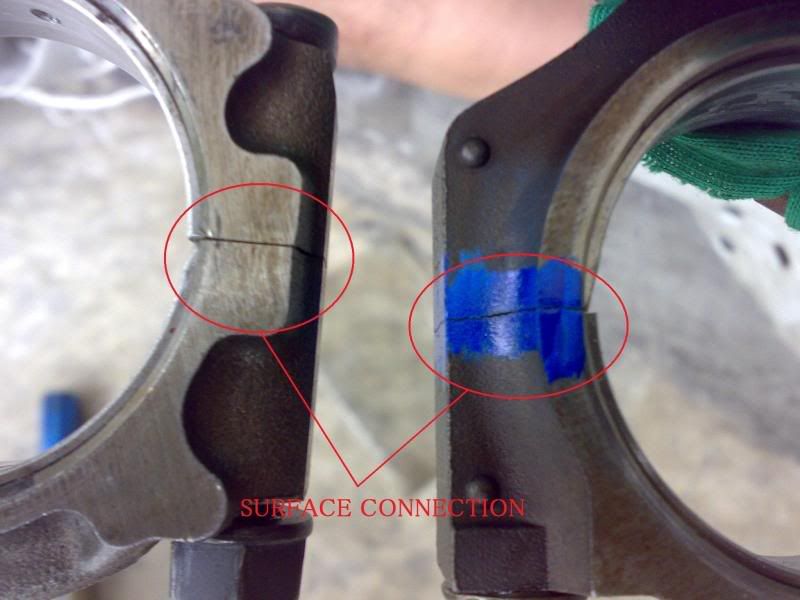

IMAGE 6

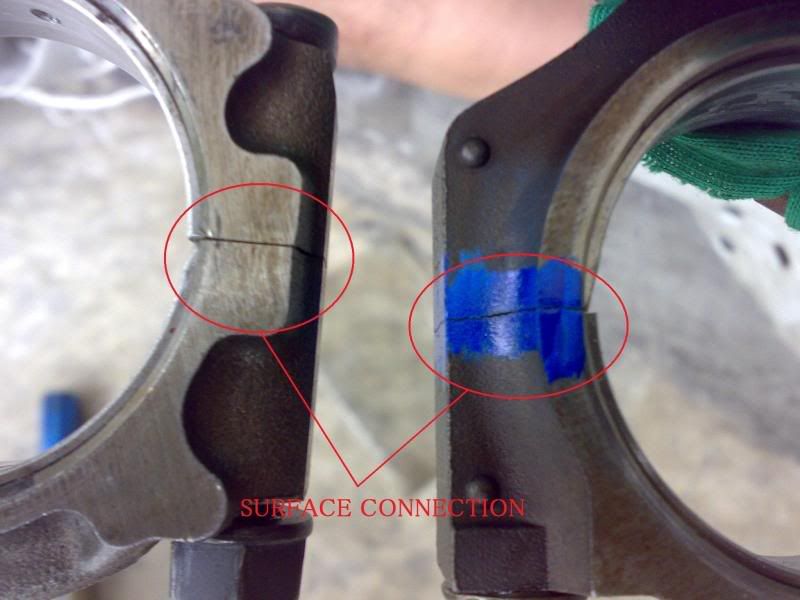

Now, lets compare the surface where the lower conrod and upper conrod have their contact. What do you think..? Would the CAMPRO CONROD seat properly flat..?

IMAGE 7

Here is the pisture showing the lower part of the CONROD attached with the upper part of the CONROD between 4G92P and CAMPRO 1.6. Obviously, after attached, The CAMPRO 1.6 are not flat at all.

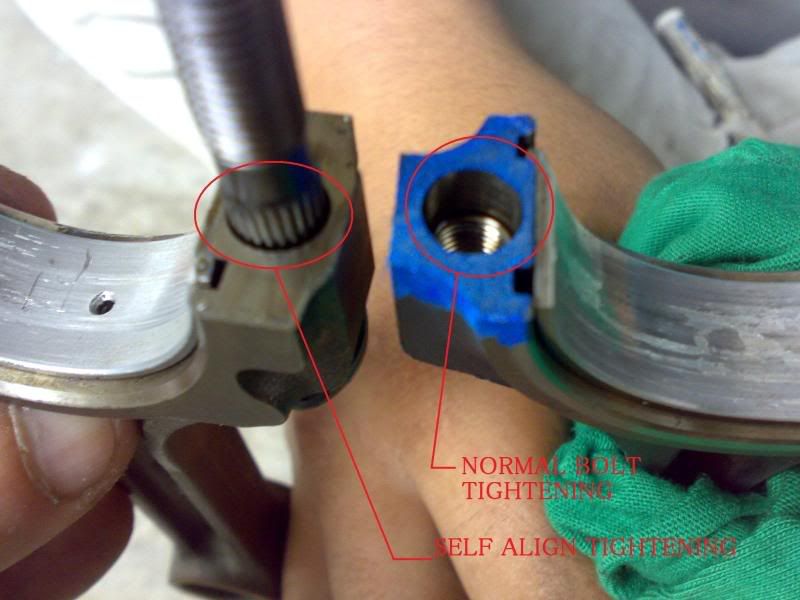

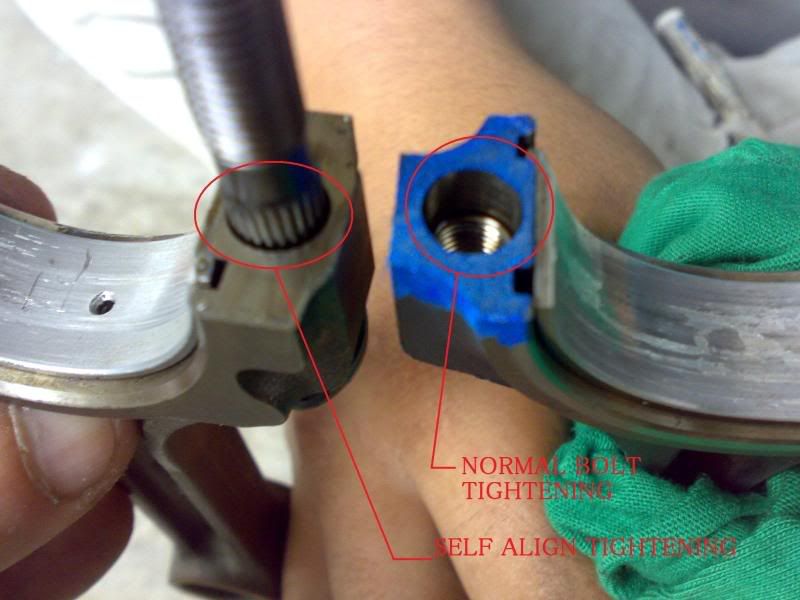

IMAGE 8

Please note the difference between the CONROD tightening method difference between the 4G92P and the CAMPRO 1.6. If u try fitting in the lower part of the MITSU's CONROD into the MAIN CONROD, U'll realize it's harder to go in at the vertical lines of the Stuts. The diameter of the portion with vertical lines are bigger so that the BOTTOM CONROD witll self align to the center of both Stuts. So, they will be flat when tightened.

Where else CAMPRO's does not use any method to aligned the tightening holes. They uses normal screw tightening method (Refer IMAGE 10). And the result, U can refer to IMAGE 9

IMAGE 9

IMAGE 10

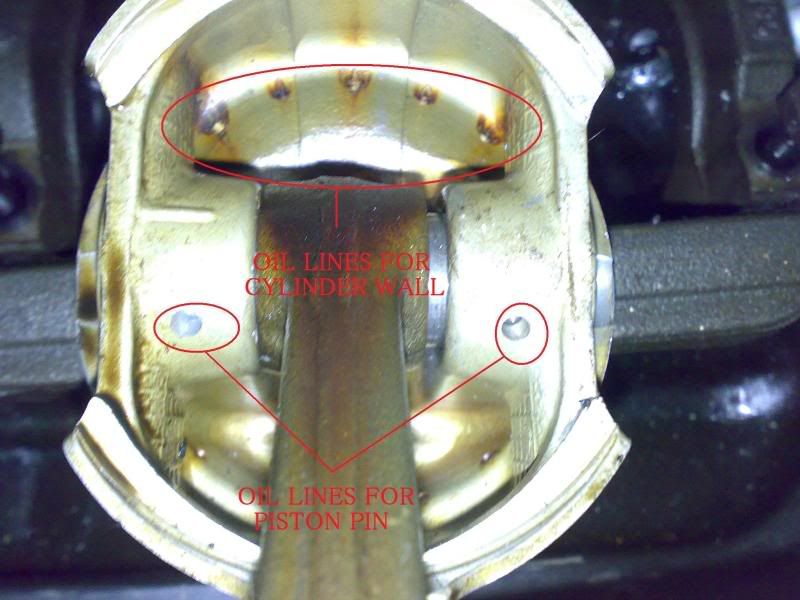

IMAGE 11

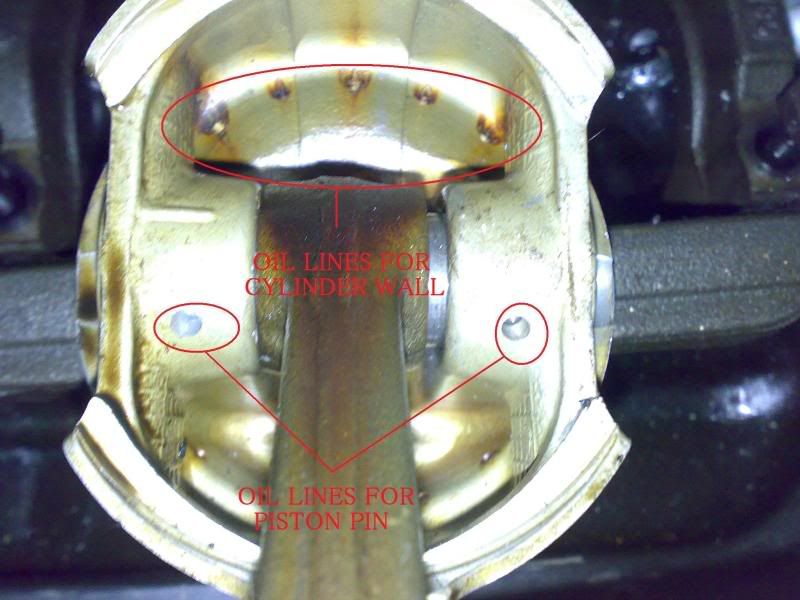

Above image shows 4G92P PISTON DESIGN

IMAGE 12

Above image shows CAMPRO 1.6 PISTON DESIGN

Obviously, the MITSU's PISTON have more holes for the engine oil to slip through to the cylinder wall for lubrication purpose compare to the CAMPRO PISTON.

Also, the Piston PIN of CAMPRO PISTON also does not have holes for the oil to slip through for the pin lubrication.

Well, not having any intention to insult, Just sharing what I know. If this is these things are designed in such a way on purpose not because of cost cutting, please clarify and prove me wrong. I am always open minded to accept. Cheers....

Thanks for reading.

As we were busy dismentalling the engine, we chat about CAMPRO 1.6 BOT failure on Crank and we realizeD BOT DOES NOT FAIL THE CAMPRO CRANK, BOT ONLY ACCELERATE THE FAILING PROCESS OF THE CRANK.

And we also realize that the cause of the Crank failure is actually from the CONROD. Here are some picture I've taken in comparison between a CAMPRO 1.6 CONROD vs a 4G92P CONROD.

IMAGE 1

The holes are for the engine oil to enter the conrod bearing for lubrication and cooling furpose as the Crank is turning within the Conrod bearing. without sufficient lubrication, the crank will wear out the conrod brearing.

IMAGE 2

An Image showing the Conrods without the bearing.

IMAGE 3

This is the CONROD Bearing used for around 100,000KM running all time on Semi Synthetic Oil. Owner claim he seldom gasak the engine. Realize that the bearing is ot smooth anymore. And sooner or later, it'll create higher friction to the cranks.

IMAGE 4

This is a CONROD BEARING from a 4G93 mitsu engine kosong from halfcut. Not sure about the date.

IMAGE 5

Take a look at the CONROD thickness comparison. Should voice anything else..? U judge.

IMAGE 6

Now, lets compare the surface where the lower conrod and upper conrod have their contact. What do you think..? Would the CAMPRO CONROD seat properly flat..?

IMAGE 7

Here is the pisture showing the lower part of the CONROD attached with the upper part of the CONROD between 4G92P and CAMPRO 1.6. Obviously, after attached, The CAMPRO 1.6 are not flat at all.

IMAGE 8

Please note the difference between the CONROD tightening method difference between the 4G92P and the CAMPRO 1.6. If u try fitting in the lower part of the MITSU's CONROD into the MAIN CONROD, U'll realize it's harder to go in at the vertical lines of the Stuts. The diameter of the portion with vertical lines are bigger so that the BOTTOM CONROD witll self align to the center of both Stuts. So, they will be flat when tightened.

Where else CAMPRO's does not use any method to aligned the tightening holes. They uses normal screw tightening method (Refer IMAGE 10). And the result, U can refer to IMAGE 9

IMAGE 9

IMAGE 10

IMAGE 11

Above image shows 4G92P PISTON DESIGN

IMAGE 12

Above image shows CAMPRO 1.6 PISTON DESIGN

Obviously, the MITSU's PISTON have more holes for the engine oil to slip through to the cylinder wall for lubrication purpose compare to the CAMPRO PISTON.

Also, the Piston PIN of CAMPRO PISTON also does not have holes for the oil to slip through for the pin lubrication.

Well, not having any intention to insult, Just sharing what I know. If this is these things are designed in such a way on purpose not because of cost cutting, please clarify and prove me wrong. I am always open minded to accept. Cheers....

Thanks for reading.

Last edited: